APPLICATION OF PROJECT:

APPLICATION OF PROJECT:

This project was one spearheaded by HRH Dr Sheik Sultan Bin Mohammed Al Qasimi (Ruler of Shajah) and was kept under wraps for the past 4 years. The Birds of Africa Aviary forms the centre piece of the Safari and highlights the flamingo habitat.

PROJECT DESCRIPTION:

A bird aviary comprising 10,000 sqm of stainless steel woven cable mesh together with shading panels.

DESIGN / FABRICATION / INSTALLATION BRIEF

The function requirement was to create a stainless steel mesh bird aviary to both keep the birds in, as well as keep out unwanted pests. Due to the hot summer months in the Middle East an additional shading element was required. This has both a functional brief as well as providing both texture and difference in translucency to the aviary structure

STRUCTURAL SYSTEMS

A tensile anticlastic form created with structural steel and cable system. The tension element is in the form of stainless steel cables and mesh together with PVC/PES shading elements.

MATERIALS

Structural architectural steel

Stainless woven cable mesh

PVC/PES fabric

LSAA 2011 Design Award Entry (4322): Cablenet Zoo Aviaries

APPLICATION OF PROJECT

As part of a major upgrade to Auckland Zoo, Fabric Structure Systems built four new aviaries to accommodate different New Zealand bird & animal species.

PROJECT DESCRIPTION

Thirteen years in the planning and almost four years in the design and building, Te Wao Nui is Auckland Zoo’s most significant project in its eighty-eight-year history. Covering more than 20 percent of the zoo’s seventeen hectares, the exhibit showcases New Zealand species in their natural environment.

Mehler Coated Technical Textiles supplied large quantities of coated fabric for the 2015 Milan Expo.

The major application was for sun shading the two main axes of the Expo. The 85,000 sqm of fabric was essentially planar rectangular panels attached to opposing valley and ridge cables.

One important concept behind the simple forms was the re-use of the fabric following the Expo.

Other projects included:

- Iranian Pavillion (2,500 sqm)

- Ferreo Pavillion (1,600 sqm)

- Institution Bologna Pavillion (4,500 sqm)

- Tent at the entrance (6,000 sqm)

For further details see HERE

The following Large Structure Projects were entered into the 2018 LSAA Design Awards in Category 4

Category 4 "Large Structures > 1000 sqm"

4001 Macquarie University Campus Common.

4066 QUT Sports Field Car Park.

4100 Sumartran Tiger Adventure.

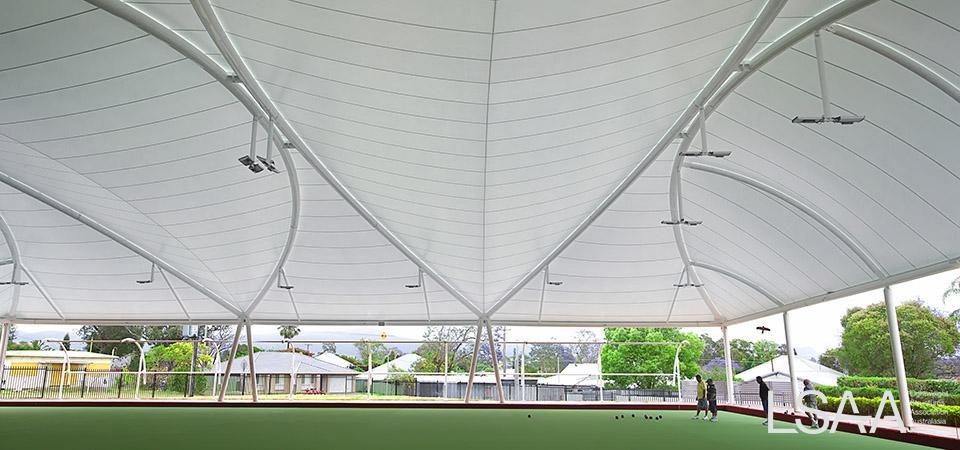

4101 Wellington Regional Bowling Club.

LSAA 2011 Design Award Entry (3185)

APPLICATION OF PROJECT:

Shading systems: The Marassi beach Clubhouse, resort villas, and spas required a large range of shading systems.

PROJECT DESCRIPTION

Marassi is a Mediterranean‐styled resort development sprawling across 1,544 acres of pristine waterfront. Situated along the magical shores of Sidi Abdul Rahman bay, the resort is close to Alexandria and a few miles away from the historic city of El Alamein.

Entrant: UFS Australasia Pty Ltd - Designer / Fabricator

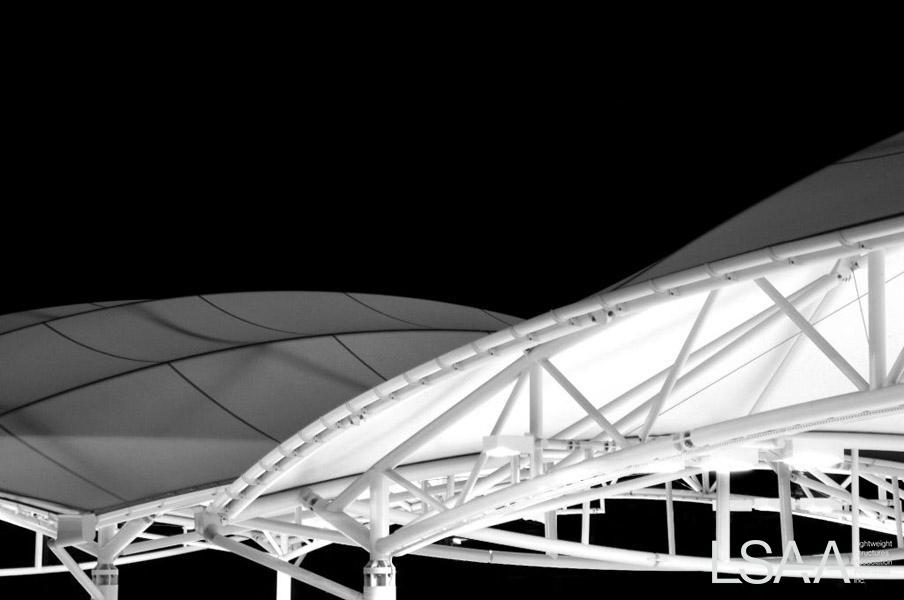

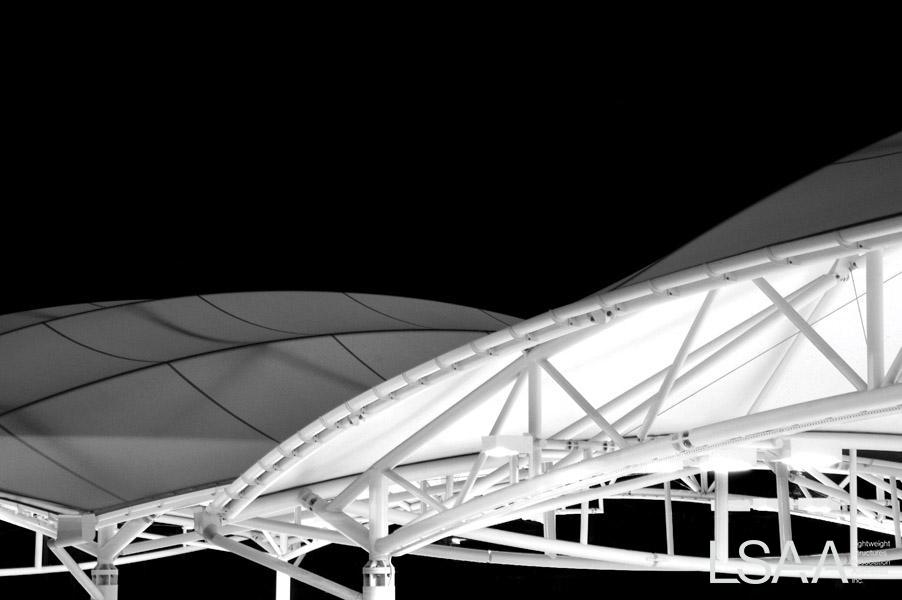

Location: 190 King Arthur Terrace - Tennyson Qld 4105

Client: Mirvac Architect: Mirvac Design Struct. Eng.: Wade Engineering

Specialist: Steel Structures Australia

Builder: Universal Fabric Structures / Ozrig

Fabricator: Skyspan Asia

This project was entered in the LSAA 2009 Design Awards, Category 3 (#37008)

Description

The Queensland State Government approved and funded the development of a first class international tennis facility for Queensland to be located in the Brisbane CBD at Tennyson. The facility offers all tennis playing surfaces, a covered main court stadium and two covered outdoor championship size show courts. The State Tennis Centre was completed in time for the Adidas international in January 2009.

LSAA Design Awards 2013 Award of Excellence (Cat 6, ID 4303)

Souk Okaz Public Theatre

Entrant: MakMax Australia

-

Location: Taif City, Kingdom of Audi Arabia

-

Client: Taif City

-

Completion Date: March 2013

Judges Comments:

"Well integrated and designed perfectly for its place."

"This looks to be very successful integration of lightweight elements with solid architecture. There's no sense that the roof has been conceived independently of the rest of the theatre. Lovely tent-like effect; very effective use of pattern on the 'fly sheet'."

PROJECT DESCRIPTION: Decorative roof, culturally significant

The purpose of Souk Okaz Public Theatre was to deliver both a functional public space for cultural activities and evocative ambience reminiscent of the ancient pre-Islamic era of a bustling Bedouin market place.

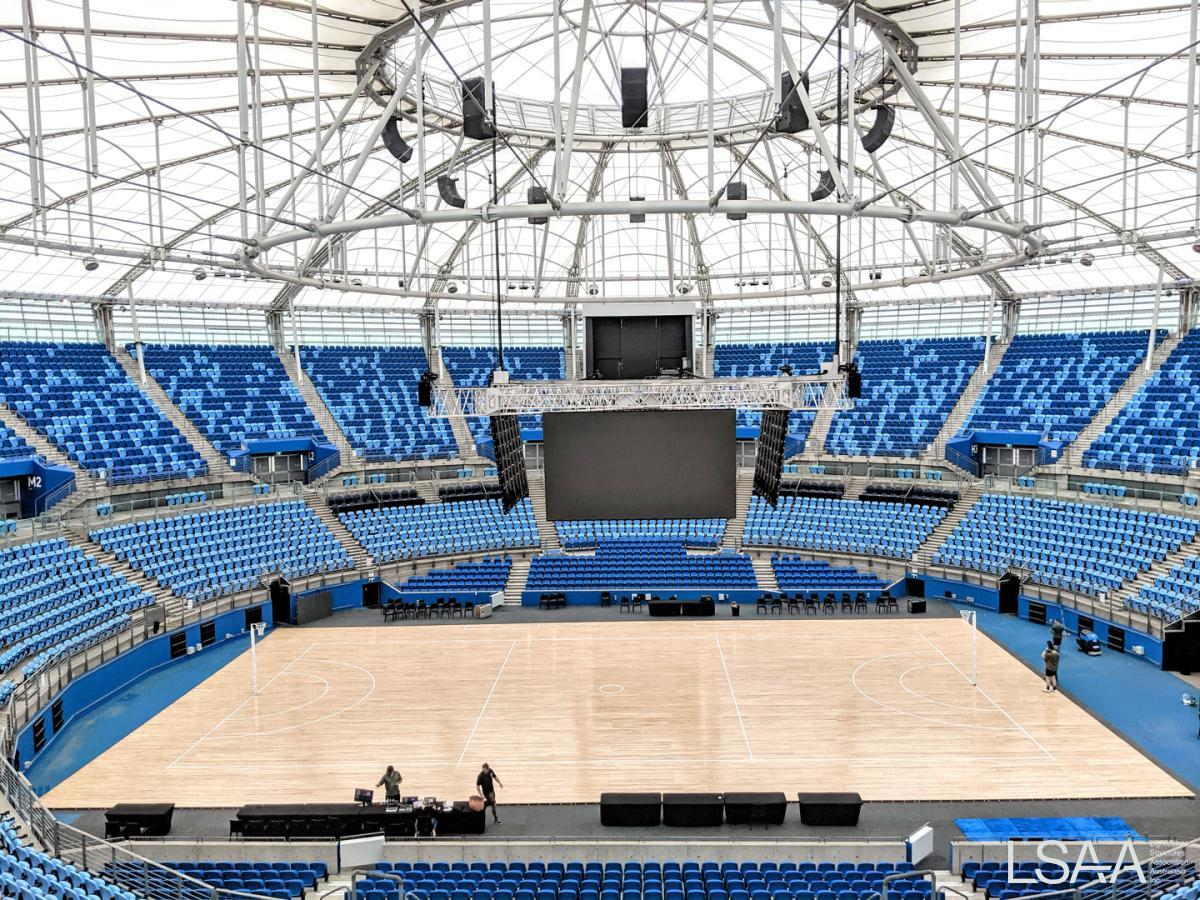

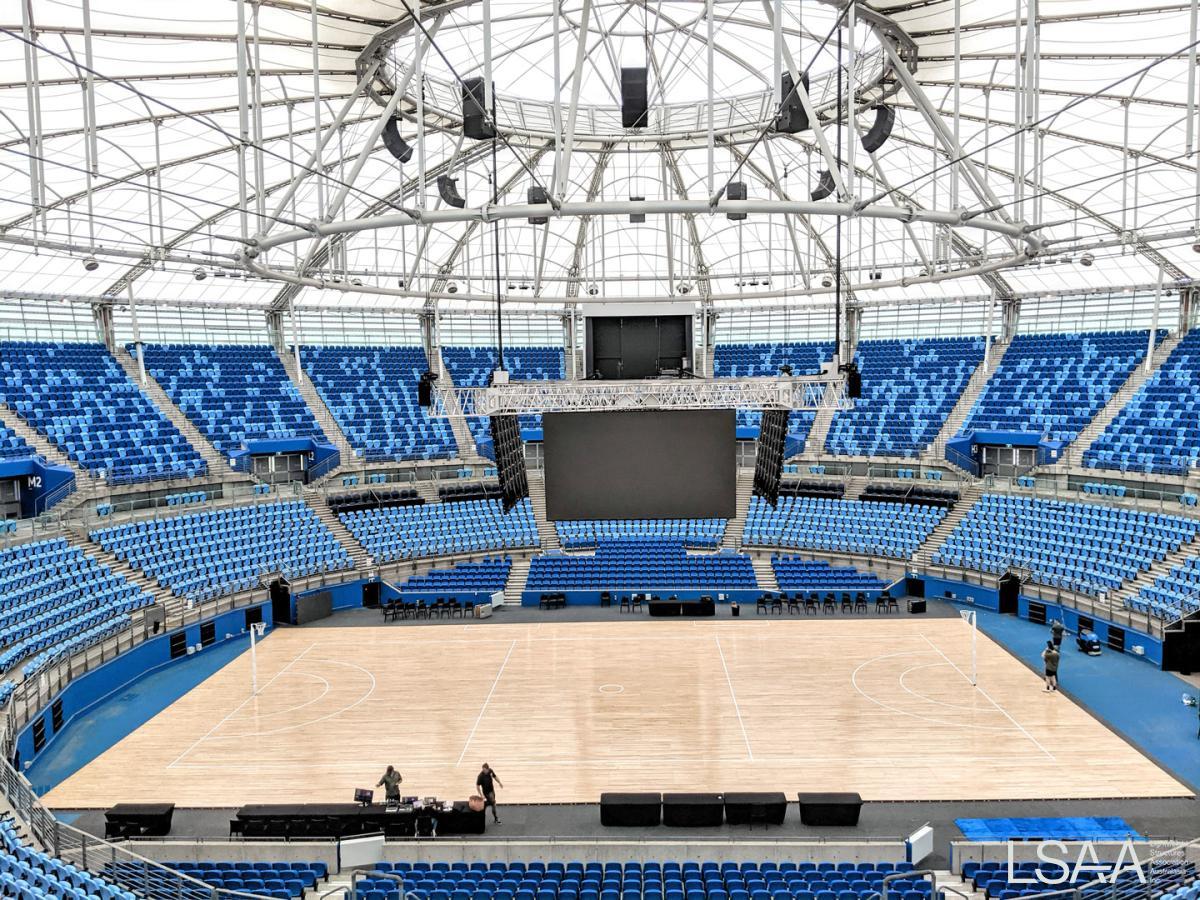

The Ken Rosewall Arena Description

The Ken Rosewall Arena project is a redevelopment project for the original stadium which was constructed in 2000 for the Sydney Olympic Games. The project included the installation of an innovative cable-tension and PTFE fabric design roof. The striking new roof is the first of its kind for stadia in Australia. The redevelopment has transformed the venue into a multi-purpose outdoor covered arena with new and upgraded facilities. The arena now operates as a multi-purpose venue, including tennis and netball, and is home to the Sydney Giants.

DESIGN / FABRICATION / INSTALLATION BRIEF

The Ken Rosewall Arena redevelopment project aimed to transform the existing tennis arena from an open-air venue into a multi-purpose indoor arena. The idea behind the roof was to allow the venue to operate unaffected by environmental impacts such as extreme heat, wind, and rain. The client requested a solution that could transform the venue into a multi-purpose outdoor covered arena with upsized in-stadia videoboards, new seating, and shade for 10,000 spectators.

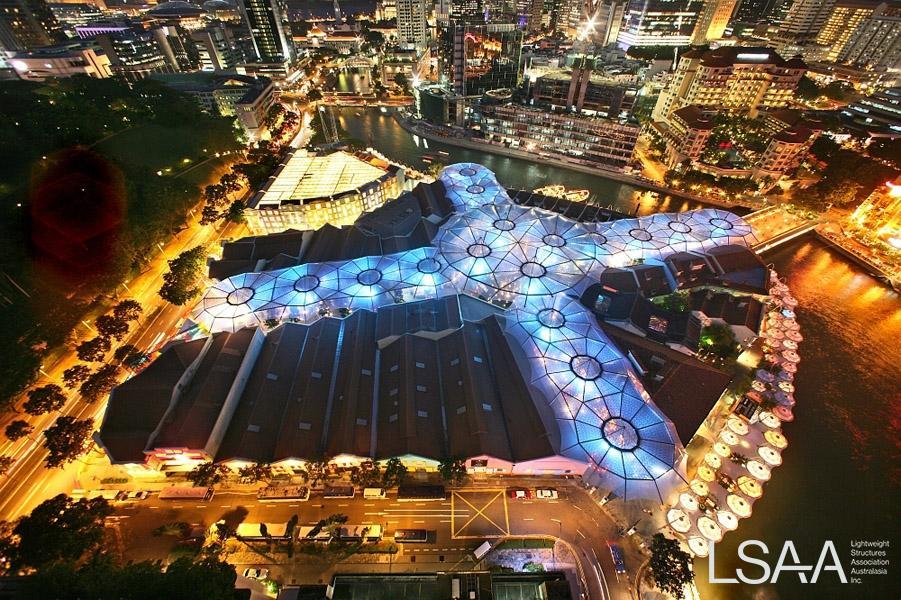

Entry in the LSAA 2007 Design Awards (Cat 4, 4007) "Large Fabric Structures"

Entrant: Tensys

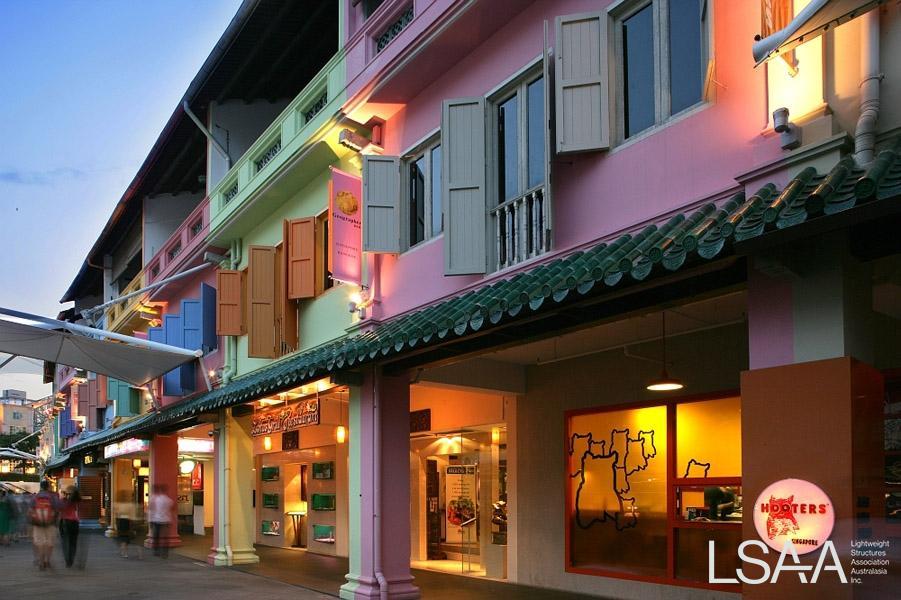

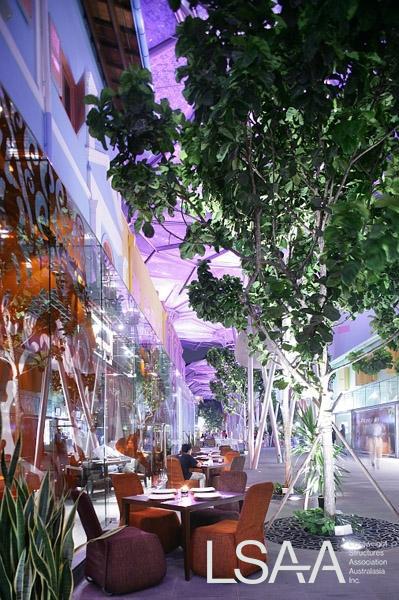

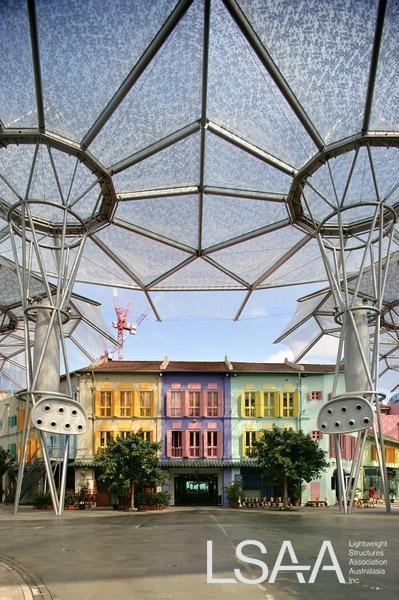

Location: Clarke Quay Redevelopment - Singapore Client: Capital and Commercial Ltd

Architect: SMC Alsops & RSP Architects Structural Engineer: Tensys

Specialist Consultant(s): Arup (Environmental) Builder: Kajima Overseas Asia Pte Ltd

Fabricator(s): Skyspan (Asia) Pvt Ltd – Riverside/Bluebell

canopies HIghtex GmbH – Street/Angel Canopies

Application and Function:

More than $50 million was spent upgrading the outdoor precinct to increase the shade and add to the comfort of visitors.

The Angel Structures are made from high performance thermoplastic film (ETFE). It is the first time this material has been used on such a large scale in Asia.

Around the river’s edge, striking bluebell canopies over lilypads revitalize the area, helping to create a new trend in outdoor dining and entertainment.

Entrant: Architectural Sails (Qld) Pty Ltd - Contractor

Location: Lot 108 Nicholson St - Greenslopes Qld 4120

Client: Ramsey Health Care

Architect: Phillips Smith Conwell Architects Pty Ltd

Struct. Eng.: Bligh Tanner & Wade Design Engineers

Others: Ozrig Pty Ltd (Installation)

Builder: John Holland Pty Ltd

Fabricator: Ruffles Engineering & Atkins Fabrication

This project was entered in the LSAA 2009 Design Awards, Category 3. (#3120)

No further details have been entered for this project

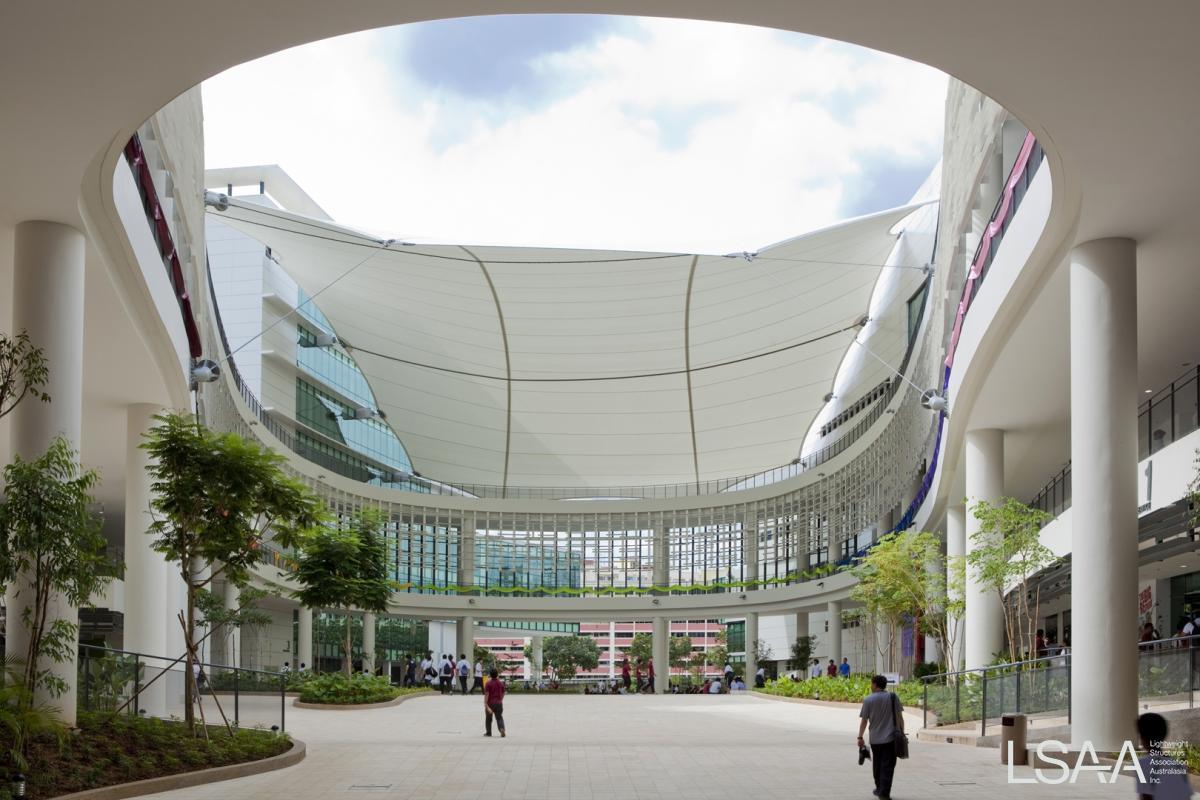

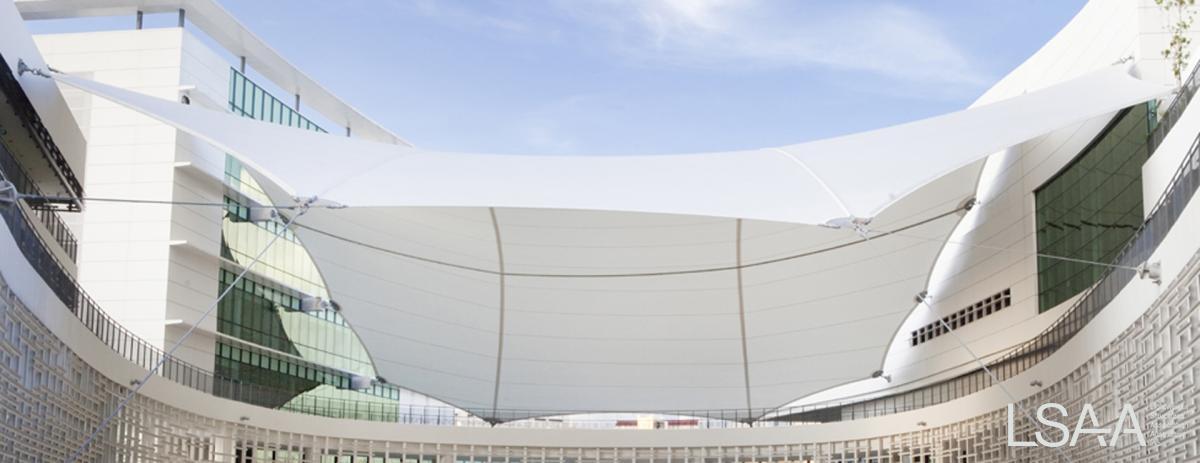

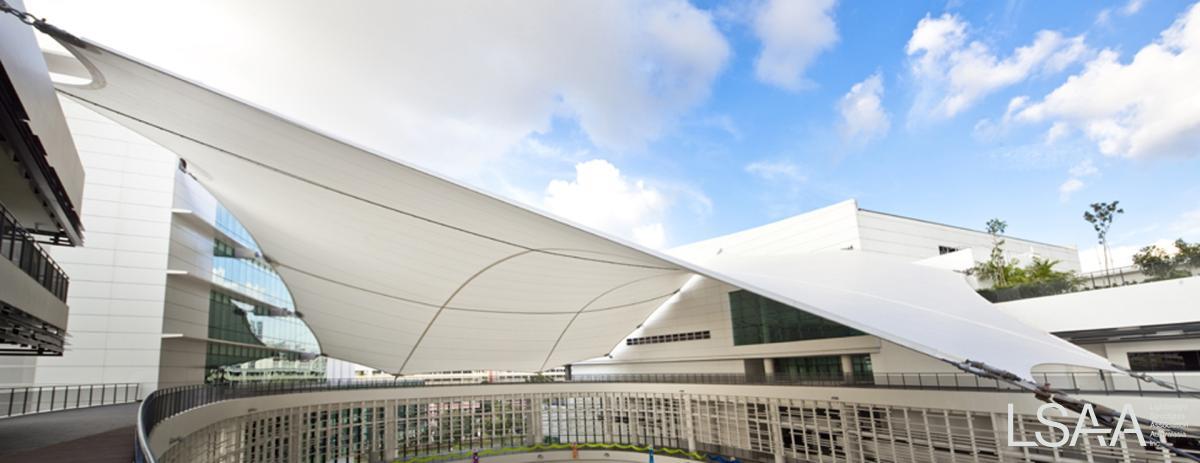

LSAA 2011 Design Award Entry (4210)

APPLICATION OF PROJECT:

Canopy shade structure: The architectural PTFE membrane canopy provides weather protection for an outdoor events plaza and exterior walkway.

PROJECT DESCRIPTION

A truly stunning piece of fabric architecture was created with this stunning lightweight membrane roof at ITE College (West) in Singapore. Supported only by a complex cable system and large steel wall plates bolted to 4 different buildings, the 3000m2 PTFE Canopy provides shelter to the Events Plaza and exterior walkways below spanning an incredible 75m span in one direction and 45m in the other.

Page 4 of 4