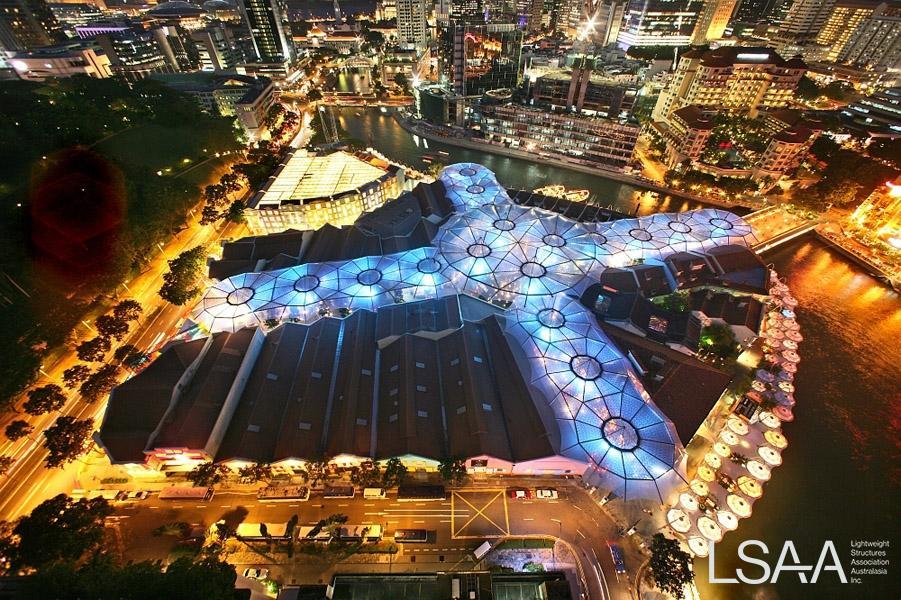

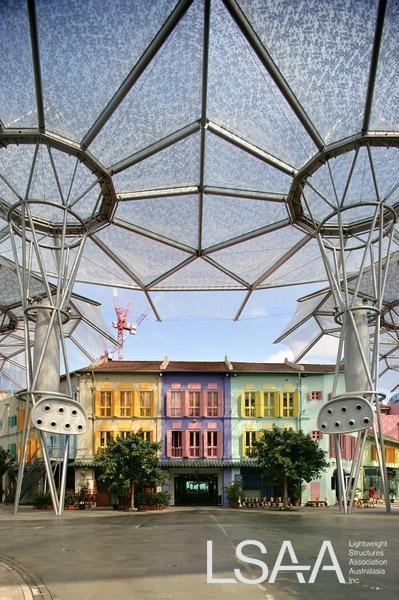

Entry in the LSAA 2007 Design Awards (Cat 4, 4007) "Large Fabric Structures"

Entrant: Tensys

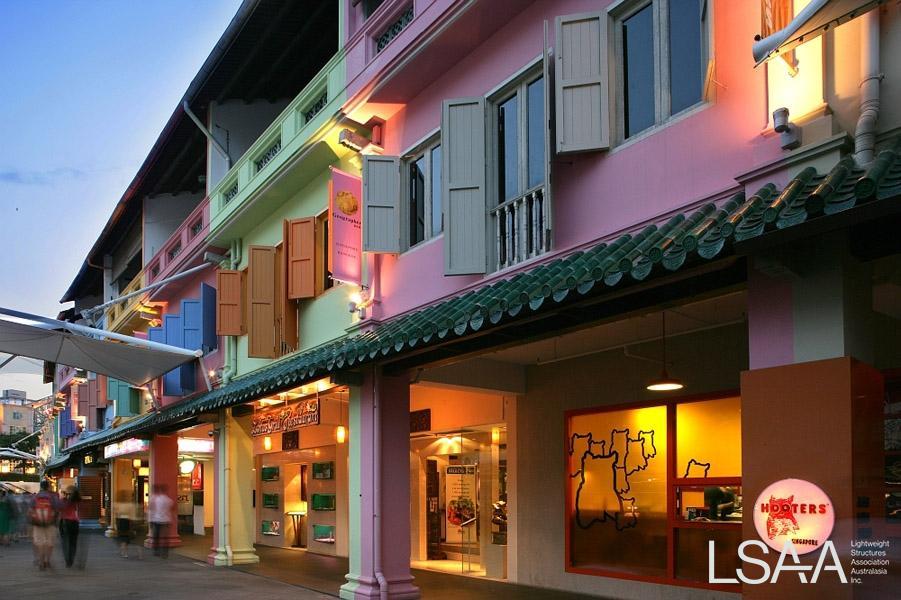

Location: Clarke Quay Redevelopment - Singapore Client: Capital and Commercial Ltd

Architect: SMC Alsops & RSP Architects Structural Engineer: Tensys

Specialist Consultant(s): Arup (Environmental) Builder: Kajima Overseas Asia Pte Ltd

Fabricator(s): Skyspan (Asia) Pvt Ltd – Riverside/Bluebell

canopies HIghtex GmbH – Street/Angel Canopies

Application and Function:

More than $50 million was spent upgrading the outdoor precinct to increase the shade and add to the comfort of visitors.

The Angel Structures are made from high performance thermoplastic film (ETFE). It is the first time this material has been used on such a large scale in Asia.

Around the river’s edge, striking bluebell canopies over lilypads revitalize the area, helping to create a new trend in outdoor dining and entertainment.

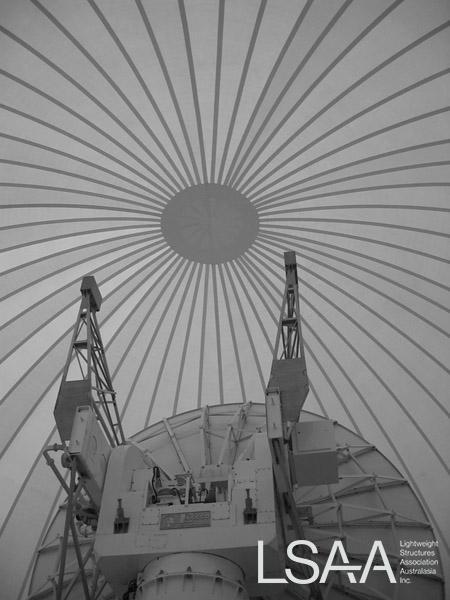

Entered in the LSAA 2007 Design Awards (Cat 3, 3003)

Entrant: Taiyo Membrane Corp

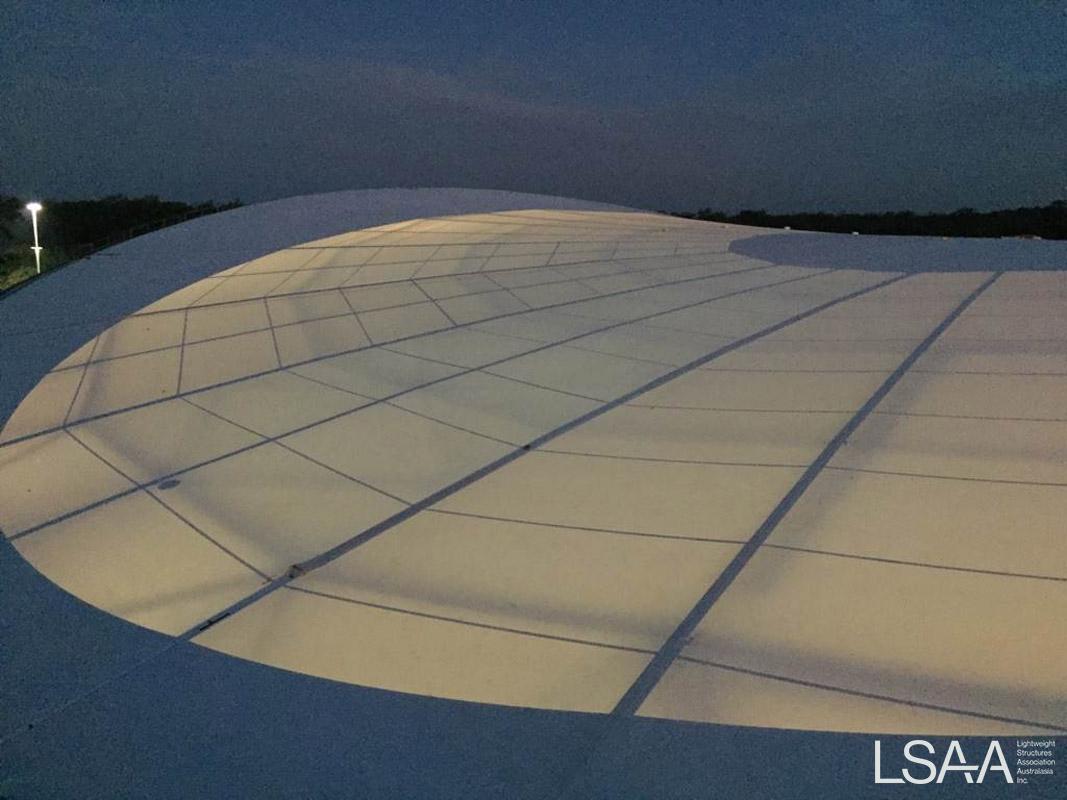

Client: Bureau of Meterology Architect: Taiyo Membrane Corporation

Structural Engineer: Michael Lester (TMC) Builder: OZRIG

Fabricator(s): Taiyo Membrane Corp

Application and Function:

Air supported structure over a radar antennae to monitor weather for the Bureau of Meterology. The structure is air supported in order to allow for minimal interference with the antennae.

APPLICATION OF PROJECT:

APPLICATION OF PROJECT:

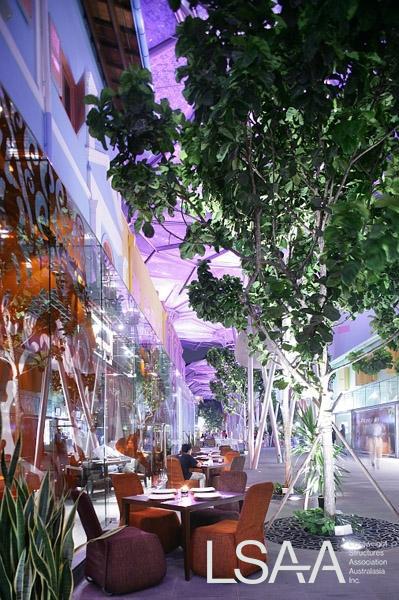

The Link Chadstone is a covered walkway between Chadstone shopping Centre and Hotel Chadstone Melbourne.

PROJECT DESCRIPTION:

The Link walkway in Chadstone is a visually stunning fabric-over-glulam structure that provides easy covered access for patrons between the Chadstone Shopping Centre and Hotel Chadstone Melbourne.

Commissioned by leading Australian real estate investment trust Vicinity Centres, and completed in October 2019, The Link is a 100m arched walkway that soars up to 15m above the pedestrian zone and is covered with 1750m2 of high-translucency THV-coated PTFE fabric.

Designed to blur the lines between the retail, commercial and leisure zones of Chadstone’s high-end fashion shopping precinct with the newly opened Hotel Chadstone Melbourne, MGallery by Sofitel, The Link transforms part of a multi-level car park into a luxurious, cathedral-like promenade for shoppers and hotel guests.

DESIGN / FABRICATION / INSTALLATION BRIEF

The designing architect’s vision of The Link was to complement Chadstone Shopping Centre’s existing vaulted glass roof with an iconic light and airy structure created with glulam timber arches, covered with a semi-translucent tensile fabric membrane.

As the membrane contractors, the design and engineering challenge we faced on The Link was to deliver a premium tensile membrane finish to complement the projects’ luxury look and feel. With the aim to link the new 5-star Hotel Chadstone to the Chadstone Shopping Precinct – the membrane finish had to embrace the high-end, luxurious aesthetic of the project.

The Glen ETFE Entry Canopy Description

The Glen ETFE entry canopy was designed to cover the outdoor food court area as part of the shopping centre’s AUD$490 million redevelopment in East Melbourne.

Fabritecture completed the design & construction of a steel and single-skin ETFE clad canopy to provide protection for patrons from the wind & rain in the outdoor dining precinct. The client also desired an aesthetic feature roof with custom artwork printed into the ETFE that would be synonymous with the culture of the surrounding area and that would enhance the overall look and feel of the Centre.

Entrant: MakMax Australia

-

Category: 4 ID Number: #4302

-

Location: Brisbane Domestic Airport

-

Client: Brisbane Airport Corporation

-

Completion Date: June 2012

APPLICATION OF PROJECT: Pedestrian bridge roof, open air.

PROJECT DESCRIPTION:

This airport terminal access project involves the construction of a major pedestrian bridge linking a new multi-level car park and train platforms to the terminal building one of the country’s business airports.

This covered walkway project is part of a larger group of construction projects which serve to improve all pedestrian and vehicular traffic at the airport.

Our client requested design, fabrication and installation of the tensioned membrane roof system. The purpose was purely weather protection for pedestrian traffic on new pedestrian access bridge.

Entrant: MakMax Australia – Designer

Location: Mumbai International Airport – India

Client: Mumbai International Airport Limited

Architect: Designcell

Struct. Eng.: MakMax Australia

Others: Mahimtura Consultants

Builder: Mumbai International Airport Limited

Fabricator: MakMax Australia

This project was entered in the LSAA 2009 Design Awards, Category 3. (#3832)

No further details have been entered for this project

Application: Container-mounted architectural structures for university dining hall.

This project was entered in the LSAA 2018 Design Awards (Cat 4, 4001)

PROJECT DESCRIPTION:

The Macquarie University Campus Common project comprised of the design & construction of a series of 11 container-mounted architectural awnings to cover a new temporary dining area for students. The design involved 6 market structures, 1 larger 30m x 30m ‘main’ structure, and 4 awning structures. The main structure was required to have an internal environmental control system for temperature regulation inside.

The intention of the temporary solution meant that the design allows for the structures to be easily dismantled and relocated in 5 years.

Photo Credit: Michael Anderson, Paramount Studios

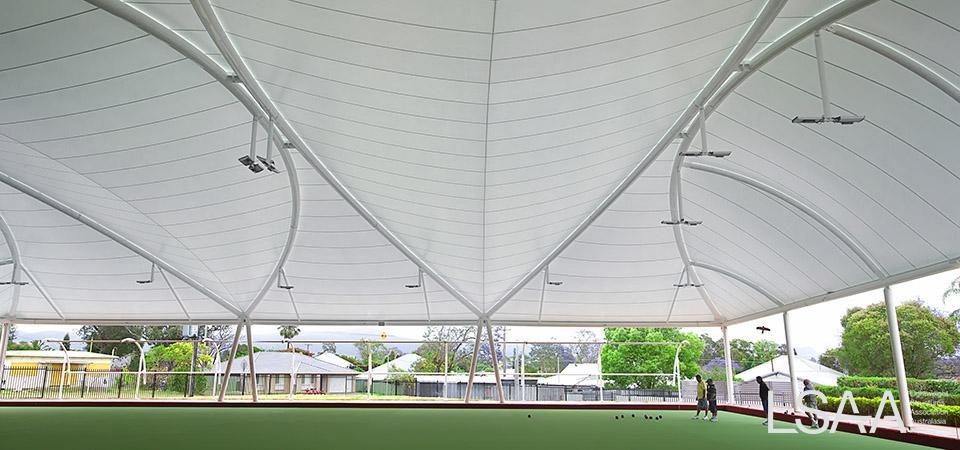

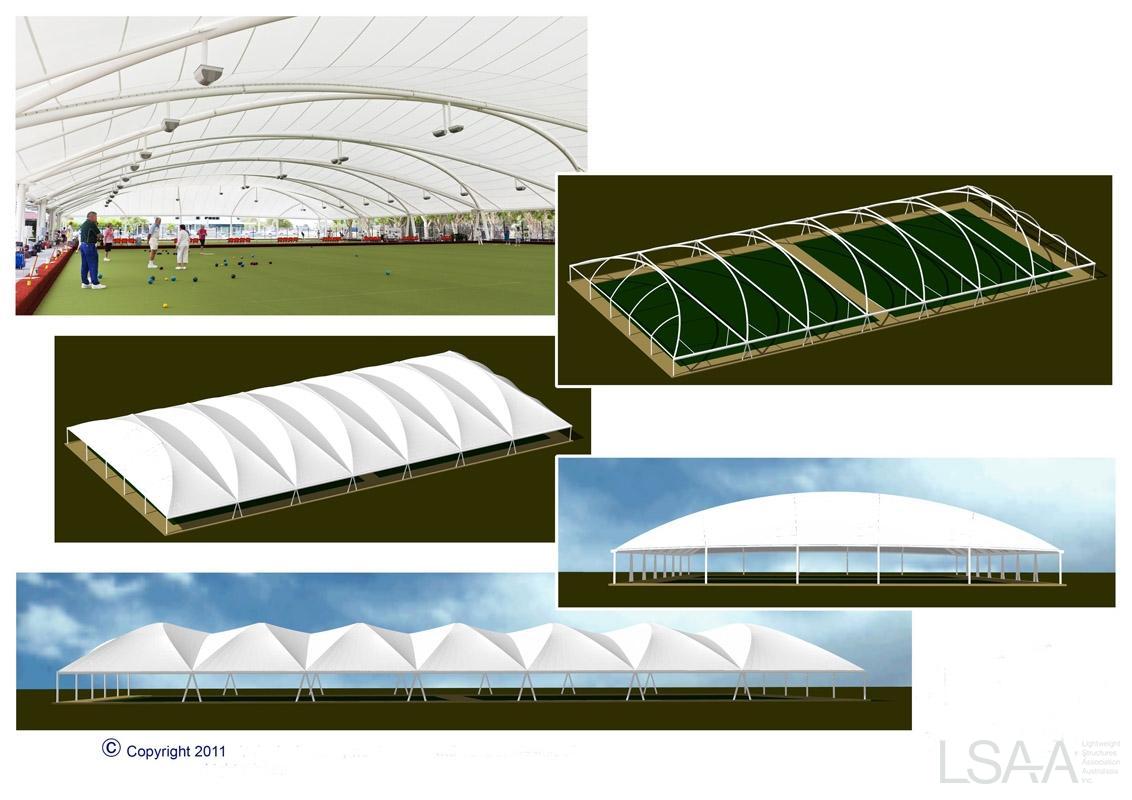

LSAA Design Awards 2013 High Commendation (Large Structures, 4351)

Entrant: Light Weight Structures

- Location: Mooloolaba

- Client: Mooloolaba Bowls Club

- Completion Date: November 2011

Judges Comments:

"An elegant project - the best of the bowling club offerings. As well as taking care of core business, the structure lends some design distinction to a town not oversupplied with architectural gems."

LSAA 2011 Design Award Entry: Cat 4, (7008) Panoli Gate - India

PROJECT DESCRIPTION

As a flagship development in the area Panoli needed a striking and unique entrance. MakMax’s Indian office was able to provide a prominent entrance structure to suit. The project, Panoli Gate House presented a new challenge for MakMax engineers. The large 1,300 sqm area required shade, weather protection, as well as a plan for collecting run off. Inspired by the design and functionality of the St Tropez products MakMax already produces as standard products, engineers decided to replicate this shape and function on a grand scale.

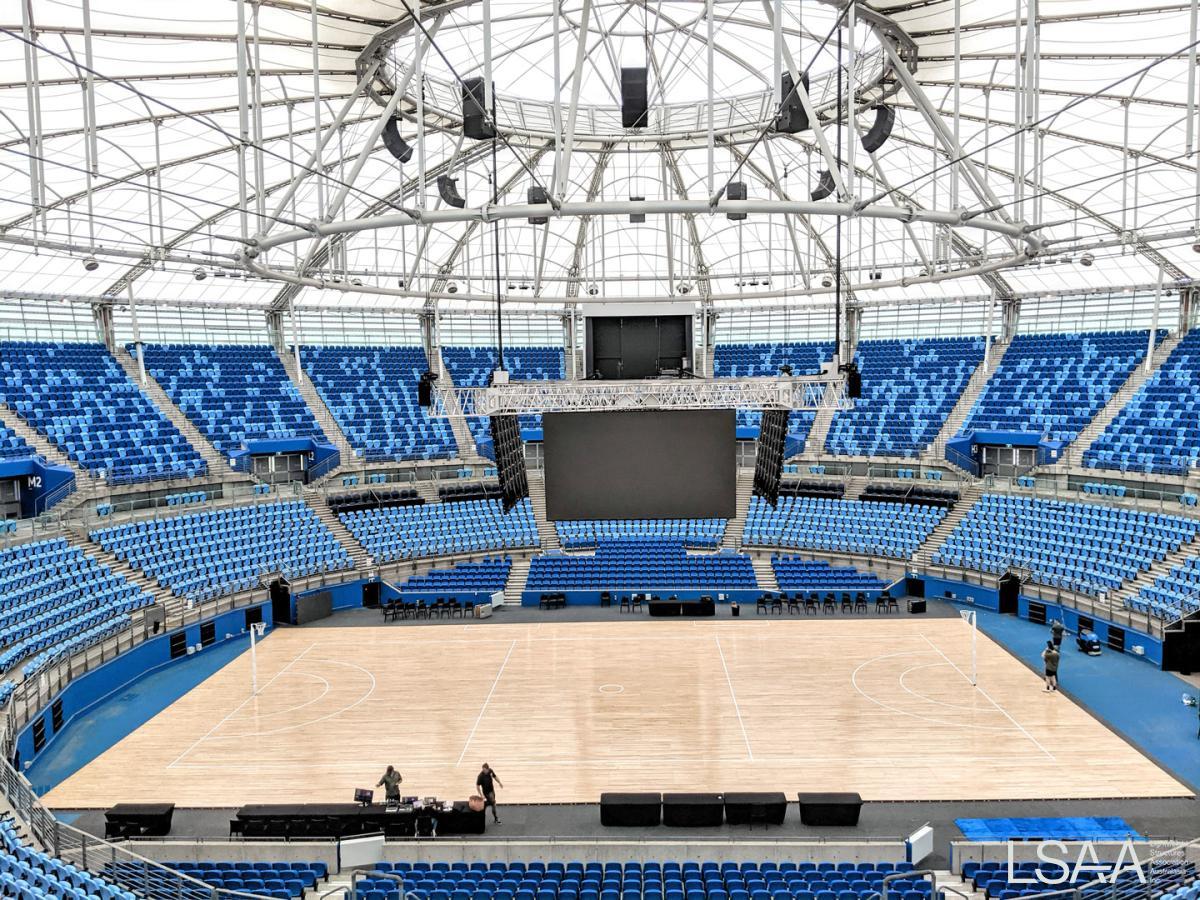

LSAA 2007 Design Award Entry (Cat 3, 3002)

Entrant: Taiyo Membrane Corp (Later as MakMax in Australia)

Client: Major Projects Australia Architect: Peddle Thorpe Architects

Structural Engineer: Xiang Du (TMC) & Connell Mott McDonald

Specialist Consultant(s): Connell Wagner (steel design)

Builder: John Holland Pty Ltd

Application and Function:

Designed to be suitable both during and after major events, the roof has been designed in two sections.

Section one is a permanent roof made from PTFE fabric. This roof covers the pool as well as stadium seating for 3,000 spectators. Section two extends the roof for “Commonwealth Games” mode.

Two temporary PVC roofs are erected either side of the permanent roof to cover a further 8,000 seats. The temporary structures create a festive effect with their high pitches and large sloping support columns.

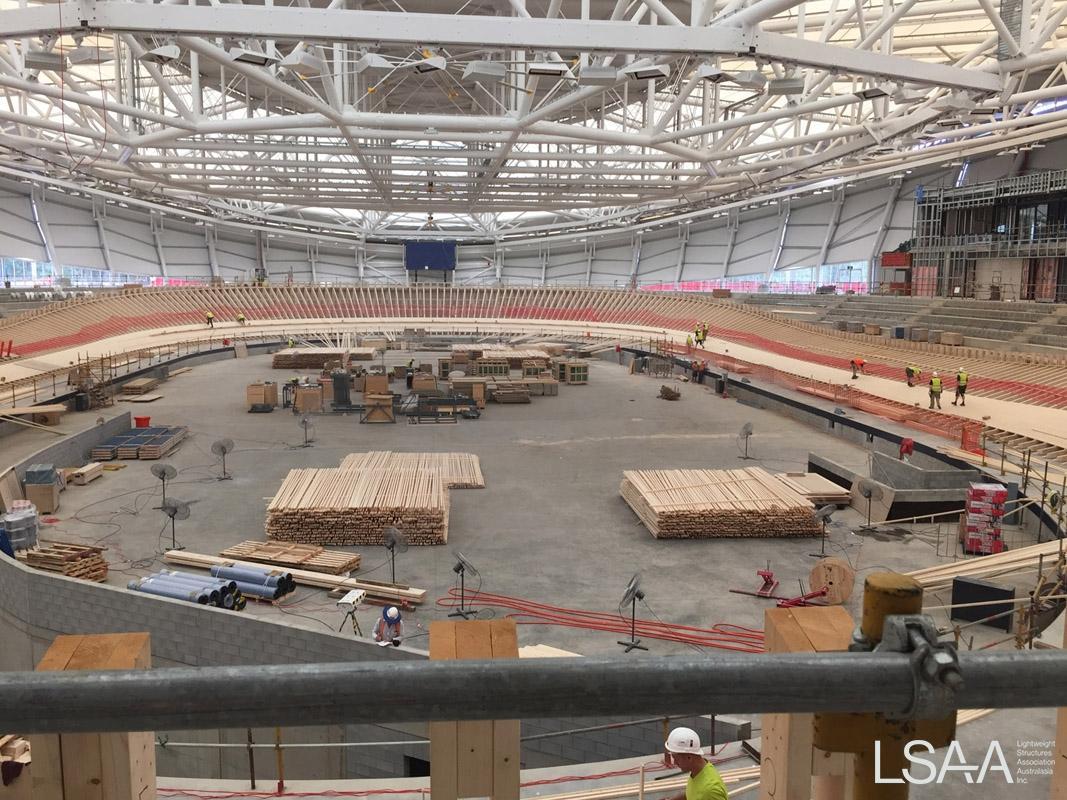

Entered in the LSAA 2016 Design Awards (Cat 4 Large Fabric Structures, 4771)

Entrant: MakMax Australia (Engineer, Fabricator, Installer)

Location: Sleeman Sports Complex, Brisbane. Completed: August 2016 Client: Watpac

Team: Cox Rayner Architects, Tensys, Arup, MakMax Australia

Application: Cycling Velodrome / indoor stadium

APPLICATION and DESCRIPTION OF PROJECT:

The creation of unique Exhibition Pavilion using these large conical forms. The conical forms to provide both shade and reprieve from the sun but also provide cooling through a passive cooling air ventilation system (reminiscent of the wind towers of traditional Middle Eastern architecture).

- Sharjah Safari - Birds of Africa Aviary (DA 2022 Entry by Tensys)

- Chevron Renaissance

- Cabramatta Bowls Club

- Marassi Beach Resort, Egypt

- The Grand Pavilion RAS

- Westlake Girls High School Sports Facility

- Auckland Zoo Aviaries

- Platypus Remediation

- Ken Rosewall Arena, Stadium Roof, Sydney

- Yogyakarta International Airport, Indonesia (2021 DA)

- Greenslopes Private Hospital Car Park Canopies

- ITE College West, Singapore

- Fabric Structures at Expo 2015

- Inglis Selling Centre Fabric Roofs at Warwick Farm Racecourse (2018)

- Brisbane State Tennis Outdoor Show Courts

- Souk Okaz Public Theatre

- Marrara Tennis Centre Fabric Roof Project (2018)

- Waitomo Glowworm Caves Visitor Centre

- The Cloud, Auckland

- Memorial Drive Tennis Centre Canopy (2021 DA)

- Wellington Bowling Club Greens Cover Project (2018)

Page 1 of 4