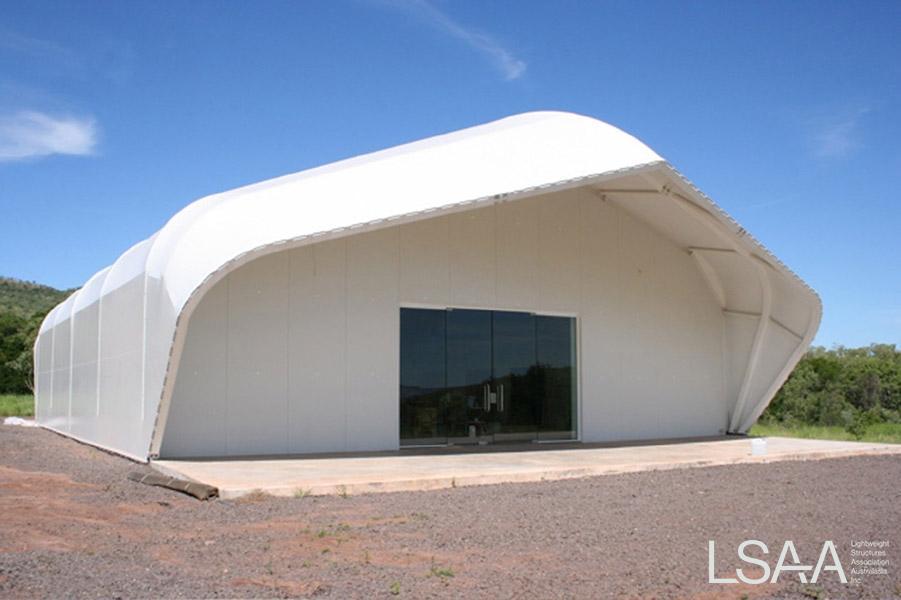

Entered in the LSAA 2007 Design Awards (Cat 2, 2837)

Entrant: UFS Australasia Pty Ltd

Client: Jirrawun Arts Pty ltd Architect: Bruce Henderson Architects

Structural Engineer: Craft Projects Specialist Consultant(s): UFS

Fabricator(s): Fabric Shelter Systems, DMG Engineering

Application and Function(s) of Project:

1. To provide an arts studio for indigenous artists to both work and display their art

2. The studio had to be designed in accordance with the severe local climatic conditions both structurally and mechanically

3. The structure required architectural flair within a unique landscape that had to be designed with the climate in mind including

a. Liner system using bondor sandwich panels

b. HVAC to provide internal comfort levels for the artists

c. Solid frame with 280km/hr wind load capabilities

d. Hoods for external shading and to keep gable ends covered

Design Brief

The architect based the design on previous UFS structures and combined the look of several to come up with a design and renders. These provided the basis for UFS to complete the design and engineering of the structures.

The combination and expertise of both teams, developed the design concept into a unique structure that provided the architect with a building solution that had architectural flair but still maintained standard building functions that the artists required.

Structural Systems

UFS’ scope of works was a complete turn key operation, starting with design, excavations and foundations, steel frame, bondor internal ceiling and walling system, APAC cooling system and patterned tension membrane outer shell..

The remoteness was the biggest challenge, UFS manufactured 90% of the building locally and shipped all components to a holding yard. All the components where carefully loaded onto two semi trailers for the long haul to the Kimberly’s. One of the biggest issues to overcome was the foundations and the hard rock that was encountered. The foundations changed detail from piers to a thickened slab. We relied on a mass of concrete to counter the extreme environmental conditions.

The footings and slab used 100 cubic metres of concrete and was laid using an on site mixing plant. It was too far from any major town to have concrete delivered using a normal concrete truck.

The location is within the highest wind load category in Australia therefore the structure had to withstand 280km/hr winds. Two cyclones have recently tested the structure with no issues resulting.

The structural steel frames (Universal Beams) where designed to withstand these loads but also had to maintain the clean lines and provide shape to give an aesthetic look for the fabric to tension over while maintain an internal shape for the bondor lining system to fit snugly and minimize difficult angles.

The wall and ceiling is completely encapsulated with Bondor panels to aid in the size of cooling system required. An APAC system was used to again counter the climatic variations of the area and provide an internal environment that was comfortable for the artists. It also provided a solid wall which allows the artist to display their works.

The final result is a practical structure that functions for the artists needs in an extreme location while providing a unique contrast with the landscape.

Materials

Frame: Structural Steel -Universal Beams Painted - strong and allowed easier detailing for walling and ceiling system

Fabric: Ferrari 702S White Opaque

Lighting: Fixtures to provide house lighting - Hi Bay system

Ventilation: APAC Air conditioning system specifically suited for internal area and local climate conditions.

Other Features: Concrete Slab & Footings, Double Glazed Front Doors, Vehicle Access Door, Inner Liner System using foam insulated colorbond steel panels (bondor) and Gable Wall Systems using foam Insulated colorbond steel panels (bondor)

Fabrication

1. Patterned fabric, plotted, and high frequency welded together to a tolerance of +- 5mm for a finished panel, two main pieces of fabric joined in the middle of the structure using special Alloy extrusions. Fabric membrane is tensioned around the perimeter using the more alloy extrusions, there are no membrane plates or cables

2. Typical steel fabrication with added details to provide shape and look to the outside of the structure - two coat paint system

3. Bondor liner system provides the perfect insulator against the harsh climate and improves the efficiency of the cooling system. It also provide a hard internal surface for hanging artwork

4. Hoods to cool and shade the gable ends and provide cover for external areas.

Construction and Maintenance

1. All components where manufactured in major cities and shipped to a common yard for loading onto two semi trailers.

2. The slab and earth works where completed prior to shipping structure components

3. Crew was mobilized to meet semis

4. Installation of steel frames, bondor panels and fabric was completed in 5 weeks

5. General maintenance to building with recommended fabric cleaning every 12 months

Costs and Comments

Total Design and construct cost - $440K

The client was ecstatic, the brief had been met, and best of all the artists now enjoy an excellent working and exhibition environment. All with a revolutionary UFS Structure.