Project entered in the LSAA 2016 Design Awards (Cat 1, Small Fabric Structures, #1290)

SEMF Pty Ltd (Architect / Engineer)

Location: Ringwood, Victoria. Completed: 31 July 2016

Client: Aquinas College

Team: SEMF, SEMF, Walsh Industries (Steel), Horizon Sailmakers (Membrane & cables)

The design brief was to Install an extension to an existing large (1550 sq m) canopy over a small area of approximately 12 sq m to provide additional sun and rain protection to existing and proposed servery windows at a school canteen.

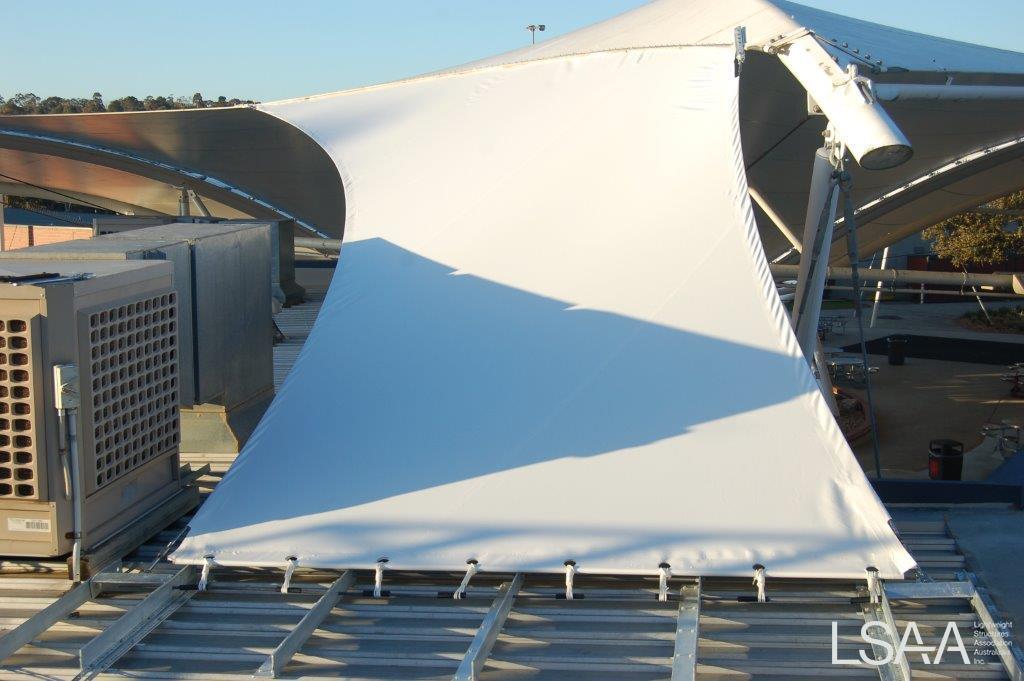

An irregular hyperbolic paraboloid shape of approximately 12 sq. m. with 2 opposite edges using catenary cables, one long edge attaching to a catenary edge of an existing large structure, and one straight edge attached to steelwork fixed over an existing metal deck roof.

The structure attaches to the edge of a much larger structure and provides increased protection from sun and rain to existing and proposed servery windows at the school canteen.

Fabric used was Hiraoka 104 T in white.

Description of Work

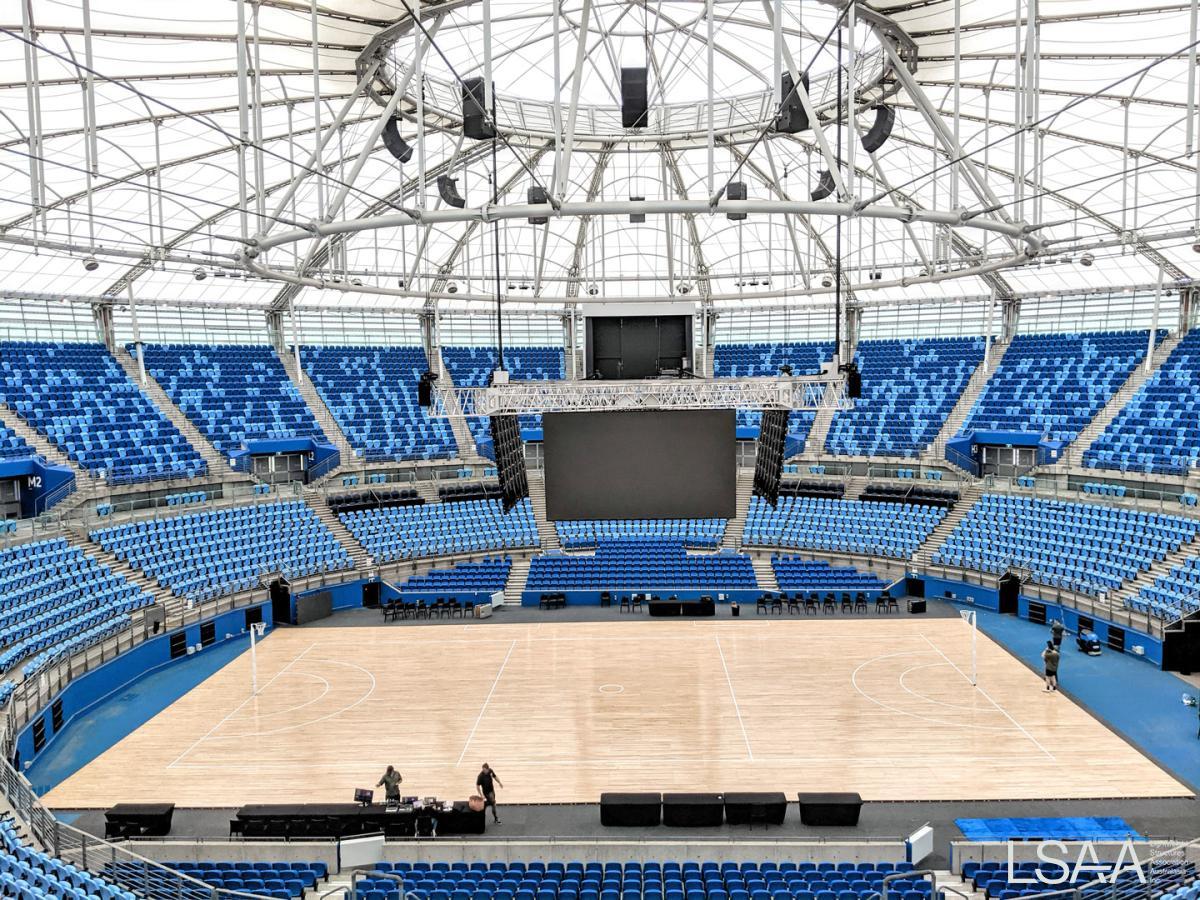

A large (1550 sq m) irregular semi toroid known as the Forum Structure was designed and constructed by the entrant in 2004 as part of a major upgrade to the school. This structure covered two servery windows to the canteen and had curved fabricated PVC gutters attached to edges to protect trafficked areas by collecting rain water runoff and discharging it to garden areas.

Changing patterns of use at the canteen and the desire to change an existing window to a coffee servery meant that the school wished to have improved protection from sun and rain along a small section of the canteen wall.

A fixed gazed canopy immediately above the windows was suggested by the Aquinas Property Manager, but the Principal was very keen to have a fabric element in keeping with the existing forum structure, which is a major element of school life.

The entrant carried out studies of sun angle and rain penetration and prepared a report with options and budget costs. The school selected a preferred option and appointed the entrant to design and construct it.

Since the structure is fixed to the roof over a food preparation area the client required the design to minimize penetrations through the roof and for the work to be done only when the canteen was not operating.

Structural Systems

The fabric shape is an irregular hyperbolic paraboloid with one straight edge, two catenary cable edges, and the other side fixed to an outward curve formed by the catenary edge cable of the larger forum structure. The geometry of the boundary conditions required the shape to be fairly flat, so there was not a lot of curvature in the fabric surface.

Simple hand analysis using load/extension compatibility was used to assess wind loads and fabric actions. This determined that a suitable level of fabric pretension was 1.0 kN/m and max fabric tension was assessed at 2.75 kN/m

The 8mm stainless steel edge cables and fittings were then sized for these loads, as was the structural steel fixed to the roof. Reactions from each edge cable were distributed to two angles screwed to the ridges of the roof sheeting with tensioned tie straps running further back over a number of sheets so that the essentially horizontal reactions were distributed into the roof structure without requiring penetrations. The connections to the roof sheeting were designed to ensure adequate load capacity and details so as to provide minimal uplift at each connection.

Steel clamping plates were bolted through the fabric of the forum structure and clamped to the existing edge cable to provide termination and fixing points for the edge cables to the new structure.

The shorter edge cable (EC2) terminated near the end of the existing edge cable and the reaction was able to be taken back into the fabric over a curved rafter frame. The longer edge cable (EC1) terminated close to the middle of the span of the existing edge cable and an additional over-fabric tie cable (TC1) was installed to carry the cable new cable forces back to the main rafter frame about 8m beyond the connection point. This prevented any undue deformations or loads being introduced into the edge cable or fabric of the existing structure.

The curved edge terminating at the existing structure was bolted to the fabric of the existing structure just inside the edge cable using stainless steel chain plates above and below and stainless steel bolts.

Materials

The fabric used was Hiroaka 104T. It was selected for having suitable strength, whilst being light-weight, having high translucency, and for the colour matching the existing Ferrari fabric quite well.

Galvanized steel was used for the main structural plates, with electrical isolation applied where these fixed to the zincalume roof sheeting.

Edge cables and clamping plates along the existing fabric edge were stainless steel. The relatively mild environment means connecting these to galvanized components is not expected to be at all problematic.

Fabrication

Fabrication details for all steelwork elements were prepared by the entrant.

The steel elements, being the attachment to the roof and at the cable connection points on the edge of the existing canopy, were installed and the geometry was site measured. This included measurement of offsets to the existing catenary edge cable and clearances to mechanical plant on the roof.

Patterns were prepared by Horizon Sailmakers, and the fabric was cut out by them using computer controlled cutting and welded using high frequency welding and 40mm seams. No preparation of seams was necessary as the fabric is weldable without abrasion.

Collaboration

The project involved collaboration between the entrant and the membrane fabricator. The membrane fabricator assisted with site measurement, patterning, site installation and tensioning.

An important criterion was to provide the necessary coverage without interfering with existing air conditioning plant on the roof, so the shape had to be developed to provide the required clearances. This was done by site measurement and the collaboration between the entrant and the fabricator.