APPLICATION OF PROJECT:

APPLICATION OF PROJECT:

Swimming pool retractable shade cover

PROJECT DESCRIPTION:

Challenged to create an innovative retractable roof for the swimming pool in the new sports precinct development for St Margaret’s Anglican School in Brisbane, Australia, we designed, engineered, developed, tested, fabricated and installed the Velarium Variable Shade System.

The Velarium shade system developed for St Margaret’s is an advanced motorised retractable shade system. This variable shade system is created using opposing sets of architectural-grade PVC mesh shade panels, supported on a cable grid that spans freely across the width of a pool. The Velarium system allows for large spans to be covered with minimal visible structural elements above the pool.

The system can be operated directly from a master control panel or a remote hand control. Each Velarium shade section is retracted and deployed by an independent motor, giving the operator the flexibility to open or close individual panel sections to suit their requirements. This clever design allows for panels to be deployed in almost any position between fully open and fully closed, and can be controlled by a single person.

DESIGN / FABRICATION / INSTALLATION BRIEF

Blight Rayner Architects initially approached us with a challenge to design and develop a retractable roof concept for the swimming pool in the new sports precinct development at St Margaret’s Anglican School in Brisbane.

Well known for our extensive portfolio of tensile membrane fabric structures for schools, universities and learning centres, we generally work in fixed lightweight tensile structures. The brief for the shade cover over the pool at St Margaret’s was to optimise the operational costs and seasonal flexibility of the pool by controlling the levels of sunshine onto the pool’s surface. This was to be achieved with a series of motorised mesh fabric panels that could open and close at the push of a button.

Our engineering team relish design challenges like this. Being designer-builders, we had the ability to design, test, check and refine our ideas to ensure what came to site would work as intended. Complexities of high cable loads, precambering of steelwork and specific erection sequences were all coordinated with the head contractor and our partner subbies. Our extensive education industry experience means the design always progressed to best meet the school’s needs and operational requirements.

STRUCTURAL SYSTEMS

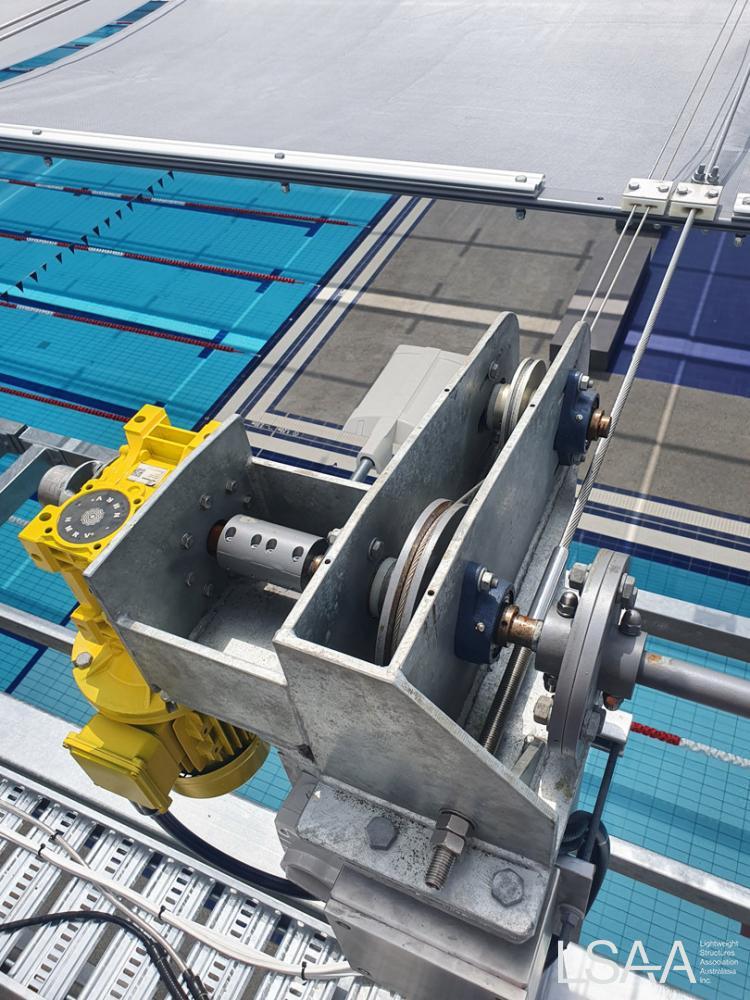

Intended to be used as sun protection while students are using the pool, the 40m x 30m space is covered by a structural grid of cables spaced 2.5m apart, which in turn support 4 opposing pairs of fully motorised fabric shade sections. The 150m2 opposing panels close from the outside, meeting in the centre. A drive cable tensioning system, including a self-balancing stainless-steel drive cable with pulley system, is incorporated into each panel section.

The roof support-system is designed for minimal maintenance by combining corrosion resistant aluminium battens with a robust stainless-steel cable-supported operating system.

We provided detailed reaction loads to supporting steel work structure to inform the structural design and required prechamber of cantilever steel truss members.

With safety at the forefront of our design for education sector projects, the St Margaret’s pool roof has been engineered to withstand sudden wind gusts of up to 125km/hr while closed, however it features a fail-safe function of automatically retracting when wind speeds rise about 27km/hr, protecting the fabric and the cabling.

MATERIALS

Soltis FT381 from Serge Ferrari was chosen for the retracting roof panels. Lightweight, durable and flexible, Soltis FT381 is a high translucency PVC mesh material that allows natural light to enter, while protecting swimmers and spectators against harmful UV rays.

The premium look, as well as the high thermal and solar protection required to shade the pool area were the main reasons Soltis FT381 was chosen for this project. Normally installed in tensioned applications, such as facades or static shade sails, a number of innovative components were engineered and incorporated into the membrane fabrication stage of the St Margaret’s project in order for the shade panels to behave in their designed manor during opening, closing and in windy conditions.

A number of innovative proprietary components were incorporated into the fabric panels to stabilise the fabric folds as the individual sections concertina in and out. Particular attention was paid to leading-edge extrusions and the fabric fixing systems to avoid the slack panel sections fouling the cables while under motion, allowing them to run smoothly along the cable grid, even in high-wind conditions.

Aluminium extrusions, which supported the leading edge of the fabric panels, were threaded onto the structural cables using bespoke nylon blocks to allow them to slide with minimal friction. The roof support-system is designed for minimal maintenance by combining corrosion resistant aluminium battens with a robust stainless-steel cable-supported operating system.

Completing the project’s low-impact visuals, the roof retraction is made possible by four 0.75kW (IP55) Electric Motors which are hidden in the upper steel structure.

FABRICATION

Key to the development of these innovative components was the construction of a full-size mock-up of one set of opposing fabric panels in the carpark of our fabrication facility. Extensive testing of each component and how they effected the behaviour of the fabric under motion ensured that the new system was proven in a practical way prior to the systems initial installation at St Margaret’s. A solid white PVC of similar flexibility and strength was used for testing to help us see the folding behaviour.

The membrane panels were fabricated in our Brisbane factory, with other structural elements, such as cables, extrusions and battens outsourced local manufactures.

COLLABORATION, CONSTRUCTION AND MAINTENANCE

With almost 700m of cables to install across a 30m open span, maintaining extremely tight tolerance in the erection of the steel structure system was vital in order to ensure the cables were perfectly straight. A few millimeters offline at one end of the structure would mean slipping or snagging cables at the other end.

A great deal of hands-on work was conducted onsite by the whole team, with our lead engineers frequently visiting site during construction phase, surveying each section to ensure structural integrity, followed by rigorous onsite testing of the moving components

For such a new, innovative application, we provided as part of the contract a series of inspections, including a close-out testing phase, a one-month full engineering inspection and a follow-up 3-month inspection top ensure the moving system was still function as expected.

COLOUR IMAGES

- 7133_01-factory-mockup-testing.jpg

- 7133_02-installation-steelwork

- 7133_04-installation-steelwork-2.jpg

- 7133_03-installation-first-panel.jpg

- 7133_05-installation-shade-panel-detail.jpg

- 7133_06-installation-support cable

- 7133_07-cable-motor-unit-detail.jpg

- 7133_08-installation-leading-battens.JPG

- 7133_09-installation-fabric-panels.jpg

- 7133_10-FINAL-1.jpg

- 7133_11-FINAL-Aerial-1.jpg

- 7133_12-FINAL-Aerial-2.jpg

- 7133_13-FINAL-Hero.jpg

- 7133_14-FINAL-Hero-2

OTHER INFORMATION

- 7133-Testing-the-Retraction-Cycle.mp4

- 7133_St Margarets Velarium Video.mp4

PROJECT CREDITS

Project ID Number 7133

Project Name St Margaret's Velarium Variable Shade

Project Location 11 Petrie Street

City / Suburb Ascot

State QLD

Country AUS

Postcode 4007

GPS Location -27.43059,153.0474413,1026m

Completion Date Sep-20

Preferred Category 7. Special Applications & Innovations

Entrant Name MakMax Australia

Address 133 Lavarack Ave

City / Suburb Eagle Farm

State QLD

Country AUS

Postcode 4009

Contact Phone Number 736335900

Mobile Number

Email Address

Website Address www.makmax.com.au

Entrant Type / Role Designer / Engineer / Fabricator / Installer

Project Client Tomkins Commercial & Industrial Builder Pty Ltd

Project Architect Blight Rayner Architects

Structural Engineer Keagan Leamy - MakMax Australia

Building Contractor Tomkins Commercial & Industrial Builder Pty Ltd

Fabricator(s) MakMax Australia

Others OzRig