Entered in the LSAA 2007 Design Awards (Cat 2, #2007, Medium Fabric Structures)

Entrant: PT Binatama Akrindo

Client: PT Summarecon Agung Tbk.

Unit La Piazza

Architect: PT Binatama Akrindo Sarjono Sam

Structural Engineer: PT Binatama Akrindo Tensys

Builder: PT Binatama Akrindo

Fabricator(s): Atkins Fabrications Pty Ltd,

PT Binatama Akrindo - Tridome space frame system + steelwork

Application: Lightweight Roof Canopy Over Café and Exhibition Stage

Design Brief

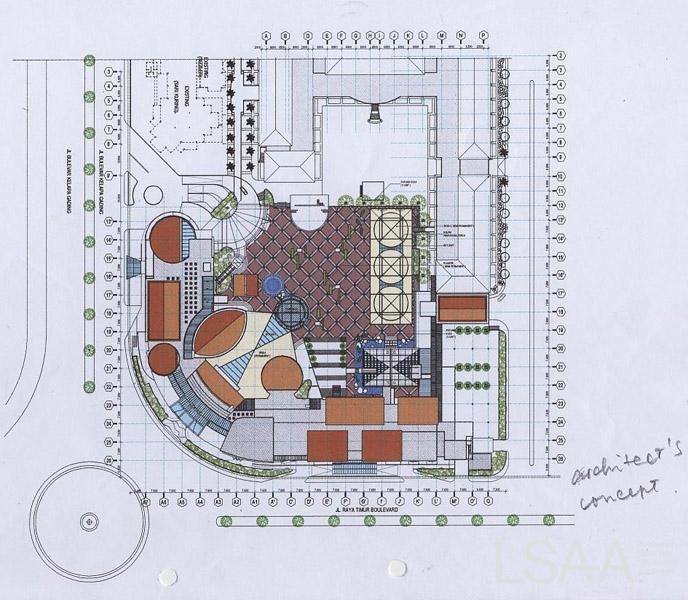

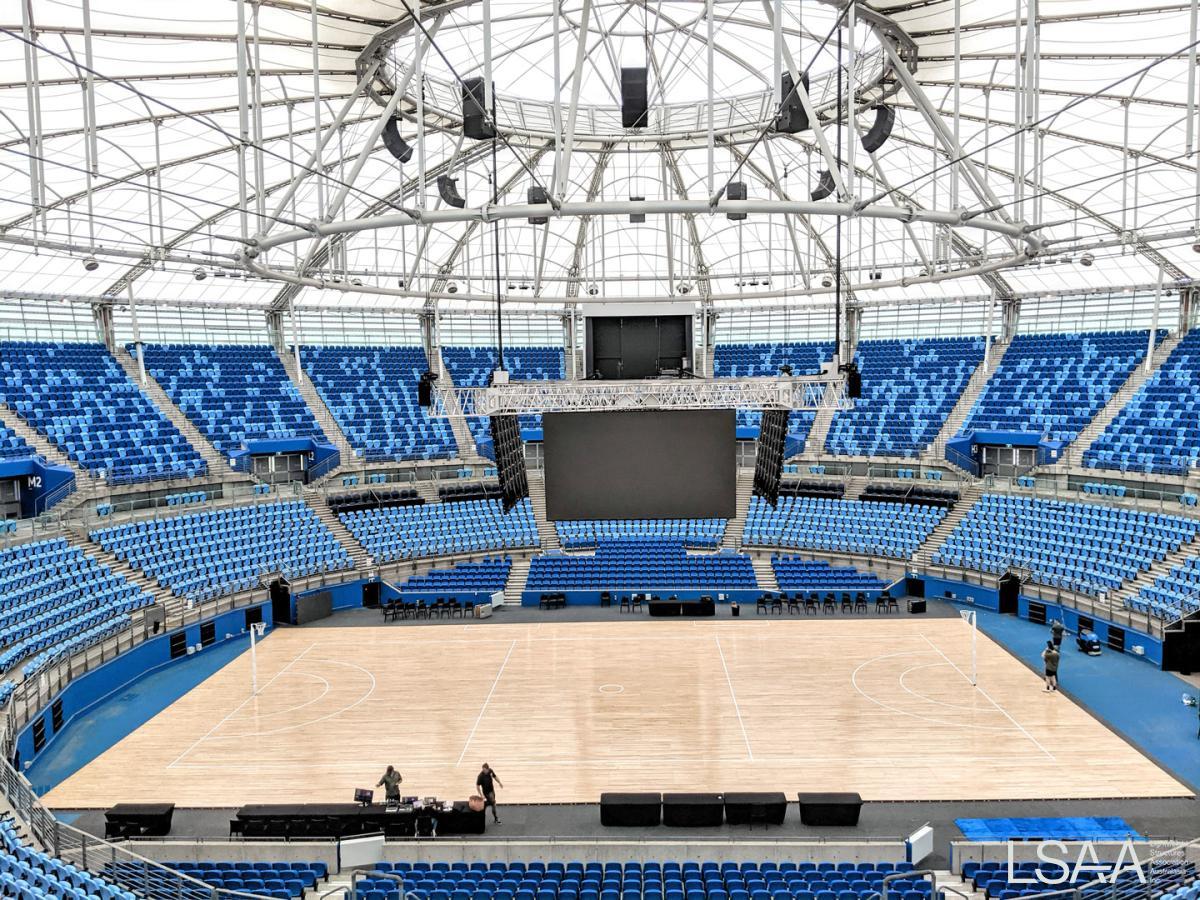

As part of refurbishment of one of the premier shopping malls in Jakarta, an open space located between three buildings (approximately 3 storeys high), we created a tensile Ferrari’s PVC fabric roof covering the space. Natural ventilation was created by having an air gap around the perimeter and central cones.

This lightweight roof creates a better use of the area for food and beverage outlets, enabling the shopping mall owners can rent this unique space throughout the year through even on hot days and rainy weather.

The fabric roof form “hugs” the buildings that it interfaces with, uniting the building masses, catching the eye and creating an invitation to patrons of the shopping mall.

The incorporation of the stage arena meant further maximization of the potential of the space for special exhibitions and events.

Structural Systems

There are many structural constraints on the design. The main one being the existing basement car parking. This provided very limited capacity and location for any new columns associated with the lightweight roof structure. External steel space frame trusses have been incorporated on top of the roof to hold the 3 buildings from moving laterally, at the same time functioning as the fixing points of the fabric, hanging the 3 cones, and holding the perimeters anchor positions in space.

Fabrication

PVC fabric (ex Ferrari of France) in combination with steel space structures ball joint system ex our own Tridome space frame system.

- The space frame components were manufactured by PT Binatama in their Tridome space frame workshop (Jakarta, Indonesia) to +/- 3mm accuracy..

- The tension fabric was manufactured (from the patterns and designs provided by Tensys), by Atkins Fabrications Pty Ltd in Australia. The tension fabric was sourced directly by PT Binatama from Ferrari

- All stainless steel cables and rigging components were supplied by Ronstan (Australia)

- All galvanized steel cables and rigging components were supplied by A Nobles & Sons Pty Ltd (Australia)

Construction and Maintenance

Since the building were not closed during renovation, extending the existing support columns where the space frame sits, and going through the existing metal sheet decking roof were very carefully done. No cranes access available for the installation ofl the 1,300 sqm fabric due to limited strength of the structure below (basement). All installation were to be carried out manually, using specially fabricated demountable scaffolding, hoists and chain blocks.

Costs: Approx $US300,000 in total