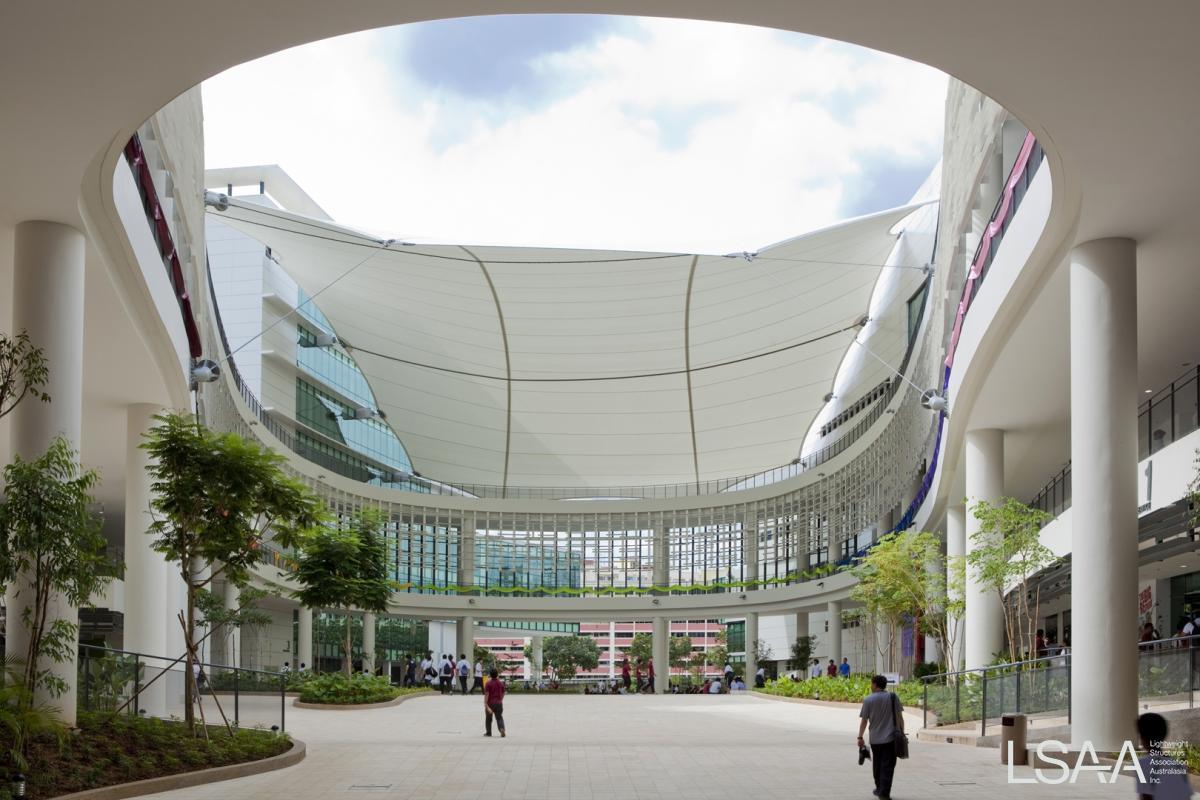

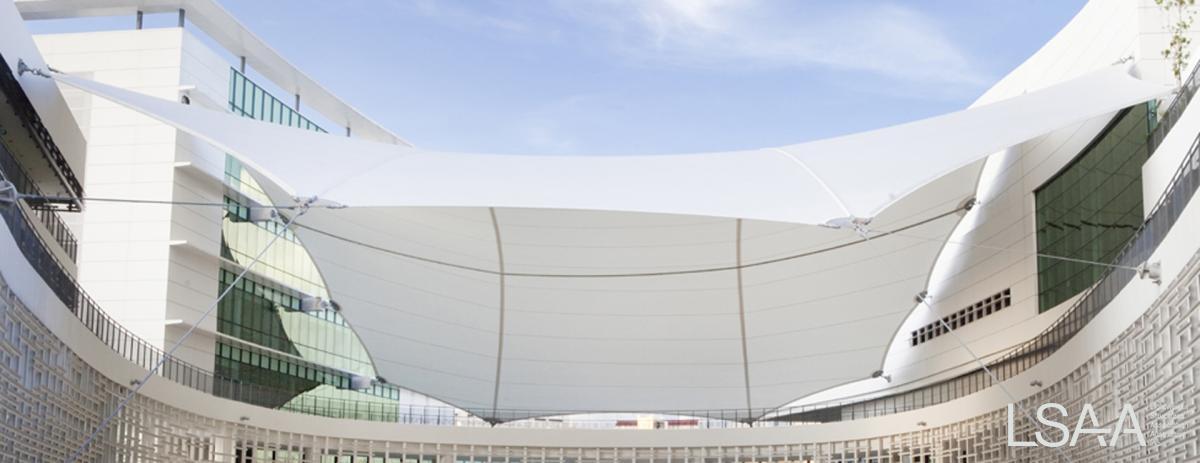

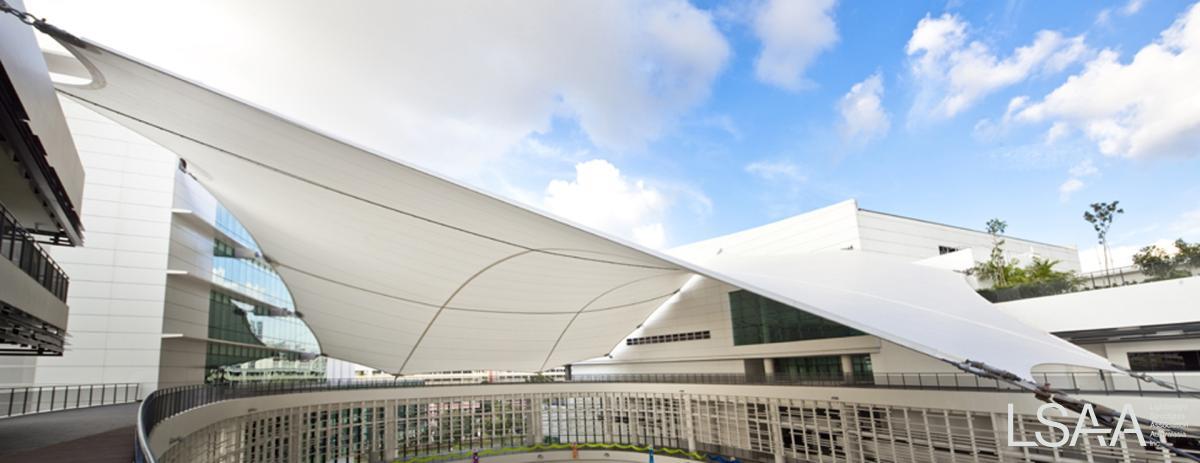

LSAA 2011 Design Award Entry (4210)

APPLICATION OF PROJECT:

Canopy shade structure: The architectural PTFE membrane canopy provides weather protection for an outdoor events plaza and exterior walkway.

PROJECT DESCRIPTION

A truly stunning piece of fabric architecture was created with this stunning lightweight membrane roof at ITE College (West) in Singapore. Supported only by a complex cable system and large steel wall plates bolted to 4 different buildings, the 3000m2 PTFE Canopy provides shelter to the Events Plaza and exterior walkways below spanning an incredible 75m span in one direction and 45m in the other.

Entrant: MakMax Australia

-

Category: 4 ID Number: #4302

-

Location: Brisbane Domestic Airport

-

Client: Brisbane Airport Corporation

-

Completion Date: June 2012

APPLICATION OF PROJECT: Pedestrian bridge roof, open air.

PROJECT DESCRIPTION:

This airport terminal access project involves the construction of a major pedestrian bridge linking a new multi-level car park and train platforms to the terminal building one of the country’s business airports.

This covered walkway project is part of a larger group of construction projects which serve to improve all pedestrian and vehicular traffic at the airport.

Our client requested design, fabrication and installation of the tensioned membrane roof system. The purpose was purely weather protection for pedestrian traffic on new pedestrian access bridge.

LSAA 2007 Design Award Entry (Cat 3, 3002)

Entrant: Taiyo Membrane Corp (Later as MakMax in Australia)

Client: Major Projects Australia Architect: Peddle Thorpe Architects

Structural Engineer: Xiang Du (TMC) & Connell Mott McDonald

Specialist Consultant(s): Connell Wagner (steel design)

Builder: John Holland Pty Ltd

Application and Function:

Designed to be suitable both during and after major events, the roof has been designed in two sections.

Section one is a permanent roof made from PTFE fabric. This roof covers the pool as well as stadium seating for 3,000 spectators. Section two extends the roof for “Commonwealth Games” mode.

Two temporary PVC roofs are erected either side of the permanent roof to cover a further 8,000 seats. The temporary structures create a festive effect with their high pitches and large sloping support columns.

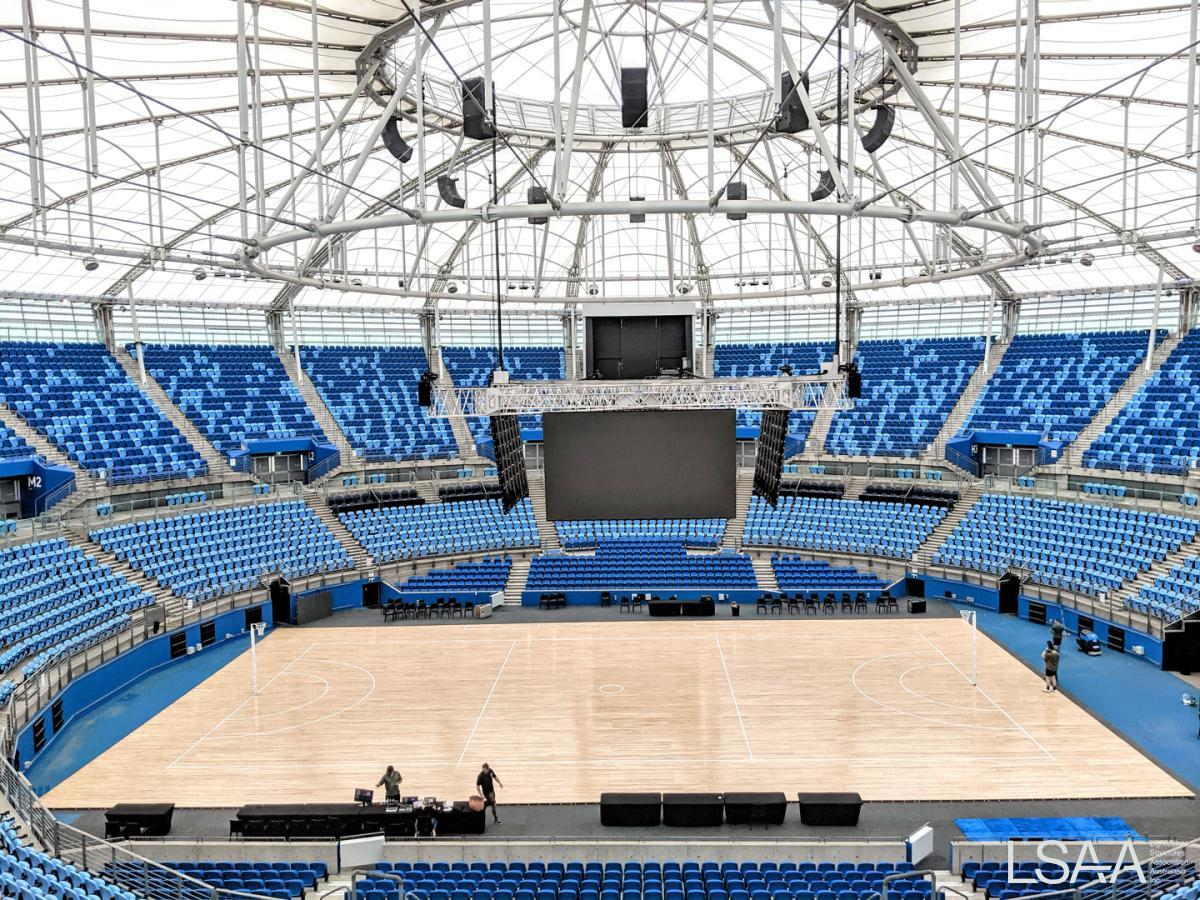

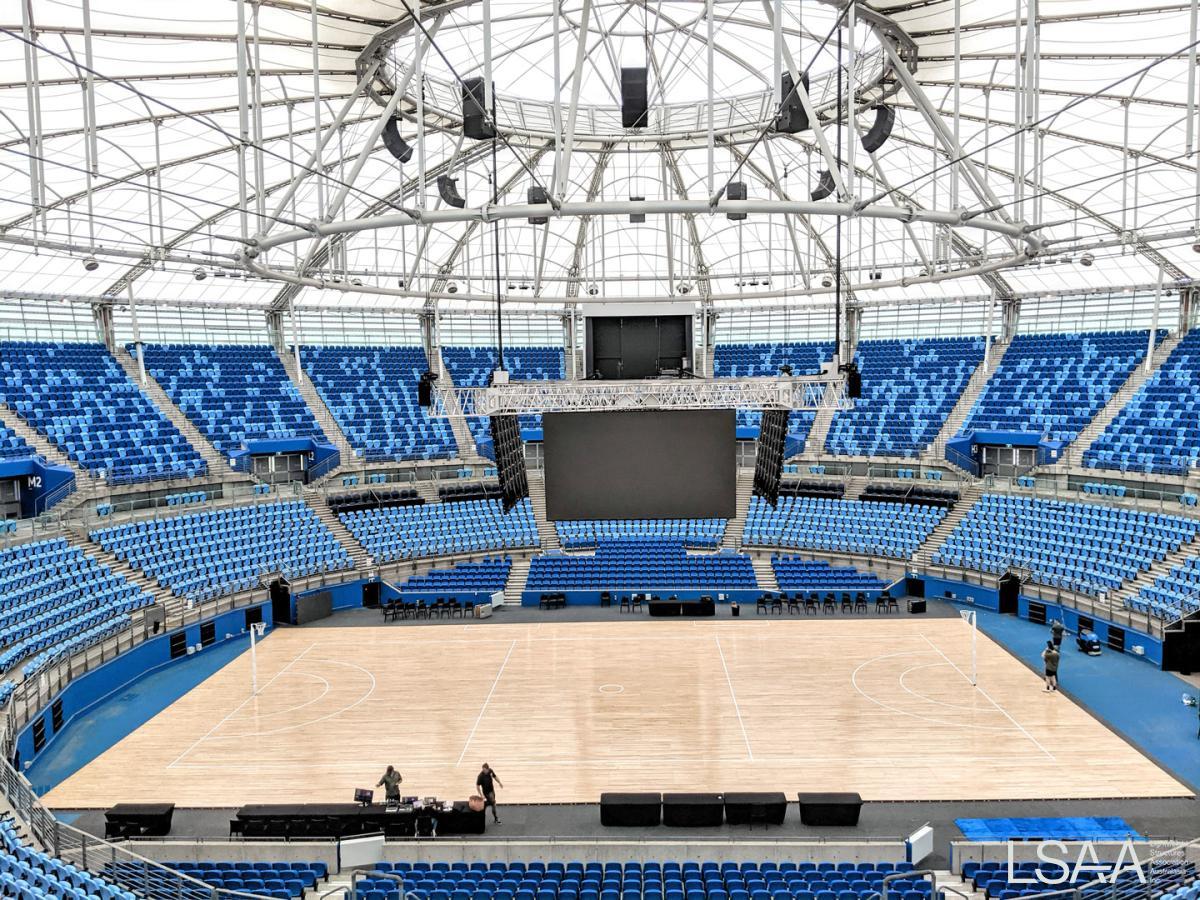

The Ken Rosewall Arena Description

The Ken Rosewall Arena project is a redevelopment project for the original stadium which was constructed in 2000 for the Sydney Olympic Games. The project included the installation of an innovative cable-tension and PTFE fabric design roof. The striking new roof is the first of its kind for stadia in Australia. The redevelopment has transformed the venue into a multi-purpose outdoor covered arena with new and upgraded facilities. The arena now operates as a multi-purpose venue, including tennis and netball, and is home to the Sydney Giants.

DESIGN / FABRICATION / INSTALLATION BRIEF

The Ken Rosewall Arena redevelopment project aimed to transform the existing tennis arena from an open-air venue into a multi-purpose indoor arena. The idea behind the roof was to allow the venue to operate unaffected by environmental impacts such as extreme heat, wind, and rain. The client requested a solution that could transform the venue into a multi-purpose outdoor covered arena with upsized in-stadia videoboards, new seating, and shade for 10,000 spectators.

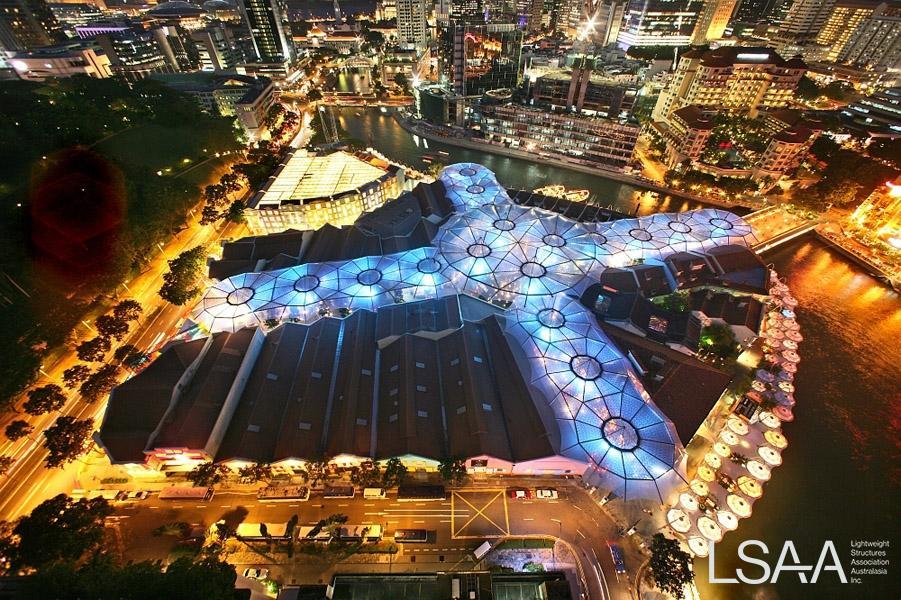

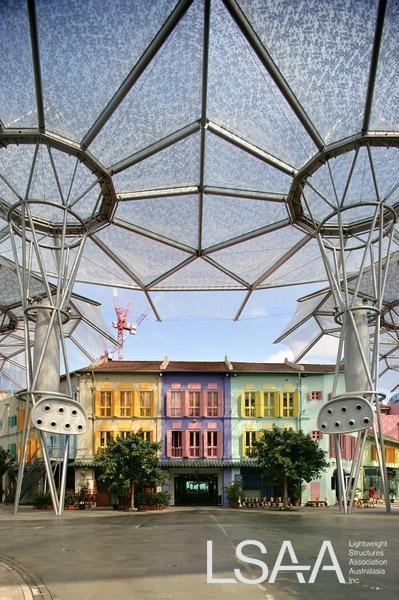

Entry in the LSAA 2007 Design Awards (Cat 4, 4007) "Large Fabric Structures"

Entrant: Tensys

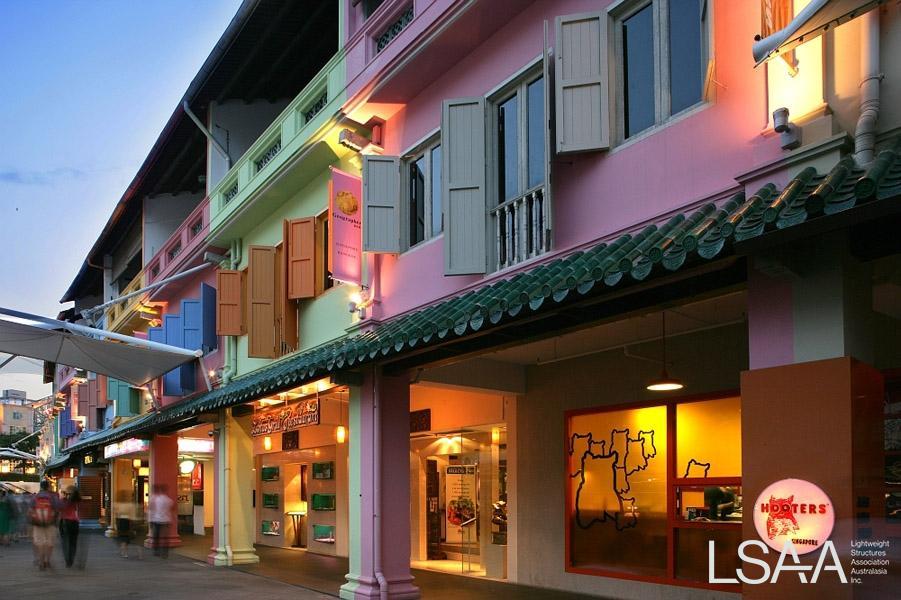

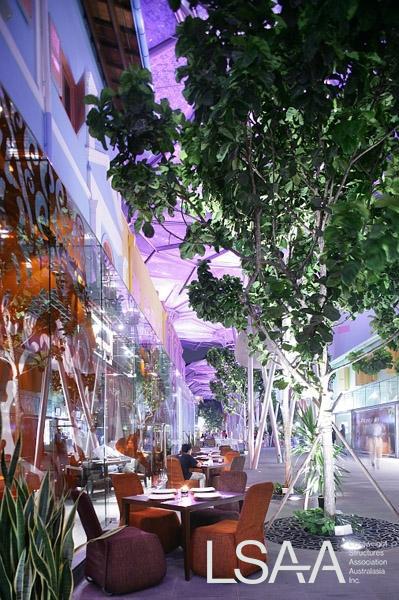

Location: Clarke Quay Redevelopment - Singapore Client: Capital and Commercial Ltd

Architect: SMC Alsops & RSP Architects Structural Engineer: Tensys

Specialist Consultant(s): Arup (Environmental) Builder: Kajima Overseas Asia Pte Ltd

Fabricator(s): Skyspan (Asia) Pvt Ltd – Riverside/Bluebell

canopies HIghtex GmbH – Street/Angel Canopies

Application and Function:

More than $50 million was spent upgrading the outdoor precinct to increase the shade and add to the comfort of visitors.

The Angel Structures are made from high performance thermoplastic film (ETFE). It is the first time this material has been used on such a large scale in Asia.

Around the river’s edge, striking bluebell canopies over lilypads revitalize the area, helping to create a new trend in outdoor dining and entertainment.

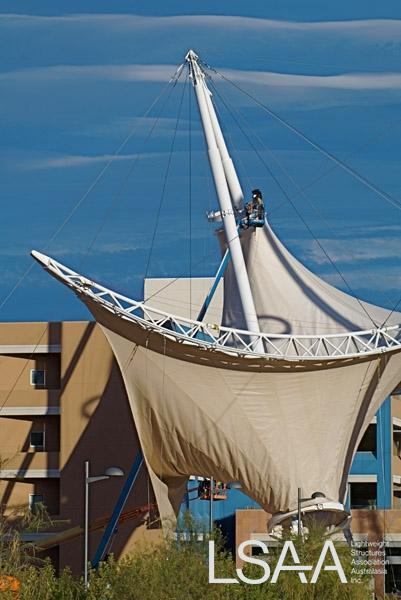

LSAA 2009 Design Award Entry (#3958): ASU – Skysong

Entrant: Atkins Fabrication (Aust) Pty Ltd – Fabricator

Location: Arizona State University – USA

Client: USA Shade & Fabric Structures Inc.

Struct. Eng.: Wade Engineering

Fabricator: Atkins Fabrication (Australia) Pty Ltd

This project was entered in the LSAA 2009 Design Awards, Category 3.

No further details have been entered for this project

APPLICATION OF PROJECT

Airport terminal drop off area roof

The New Yogyakarta International Airport (NYIA) Description

The new Yogyakarta International Airport (NYIA) at Kulon Progo Regency, serves the Yogyakarta Special Region, Indonesia, and is operated by Ankasa Pura. As part of the airport development, Fabritecture was contracted for the design & supply of ETFE pneumatic roofing as well as supply system and ducting.

The ETFE component of the roof comprises 84 2-layer cushions covers a plan area of approximately 14,314m2 and is part of an overall canopy integrating polycarbonate elements also, overall providing 18,900m2 of weather cover the exterior drop-off area.

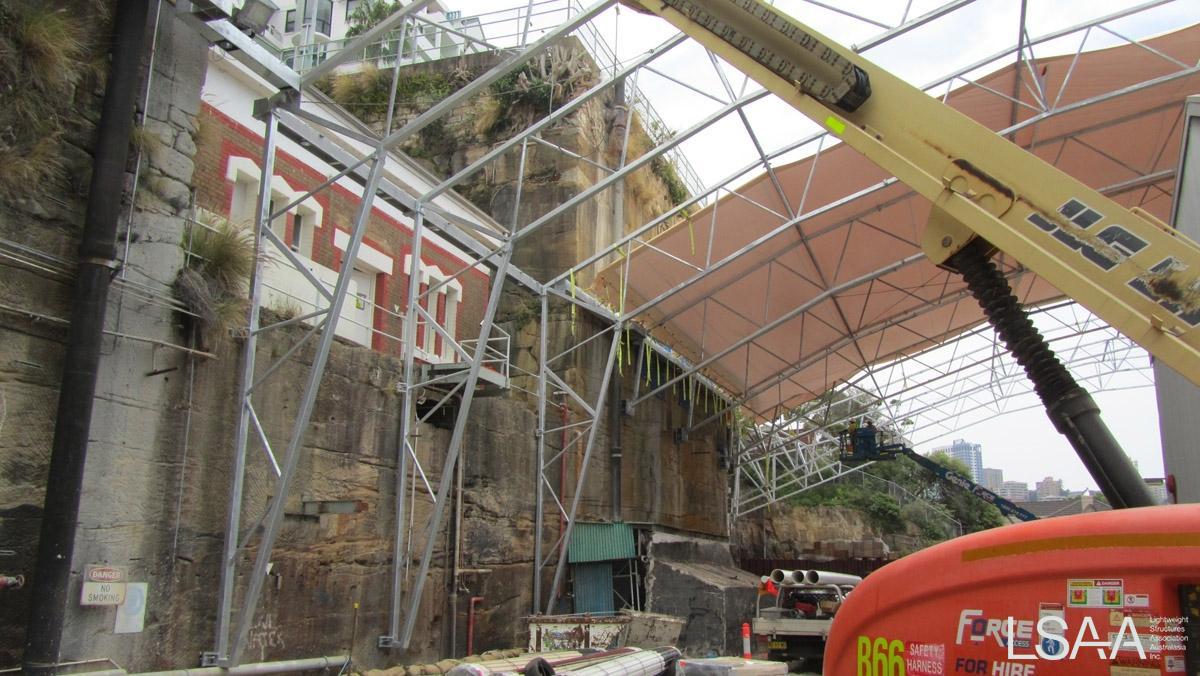

The project was entered in the 2013 LSAA Design Awards (Large Structures, #3301)

Entrant: Global Fabric Structures (UFS)

Location: Sydney

Client: Thiess Australia

Completion Date: December 2012

PROJECT DESCRIPTION:

The former HMAS Platypus site is nestled below the suburb of Neutral Bay, Sydney Australia on a quiet harbour inlet.

This site has been an integral part of the history of Sydney Harbour since the early 1800's. A gasworks, a workshop for servicing torpedoes and a base for Australian Submarines have a left a contaminated industrial site that is excavated out of sandstone and spread over several levels.

Entered into the LSAA Design Awards 2007 (Large Structures, 3195)

Entrant: Oasis Tension Structures

Client: Multiplex Constructions (Vic) Pty Ltd

Architect: Darryl Jackson Pty Ltd

Structural Engineer: Tensys

Specialist Consultant(s): Drafting Steel One

Builder: Oasis Tension Structures (Australia) Pty Ltd

Fabricator(s): Atkins Fabrications Pty Ltd Structurflex NZ,

Geelong Fabrications, Ronstan

Aside from the images below, no other details have been entered for this project.

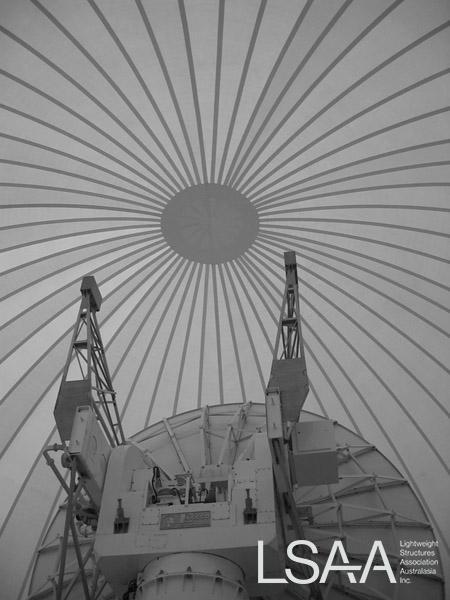

Entered in the LSAA 2007 Design Awards (Cat 3, 3003)

Entrant: Taiyo Membrane Corp

Client: Bureau of Meterology Architect: Taiyo Membrane Corporation

Structural Engineer: Michael Lester (TMC) Builder: OZRIG

Fabricator(s): Taiyo Membrane Corp

Application and Function:

Air supported structure over a radar antennae to monitor weather for the Bureau of Meterology. The structure is air supported in order to allow for minimal interference with the antennae.

Entrant: Architectural Sails (Qld) Pty Ltd - Contractor

Location: Lot 108 Nicholson St - Greenslopes Qld 4120

Client: Ramsey Health Care

Architect: Phillips Smith Conwell Architects Pty Ltd

Struct. Eng.: Bligh Tanner & Wade Design Engineers

Others: Ozrig Pty Ltd (Installation)

Builder: John Holland Pty Ltd

Fabricator: Ruffles Engineering & Atkins Fabrication

This project was entered in the LSAA 2009 Design Awards, Category 3. (#3120)

No further details have been entered for this project

Mehler Coated Technical Textiles supplied large quantities of coated fabric for the 2015 Milan Expo.

The major application was for sun shading the two main axes of the Expo. The 85,000 sqm of fabric was essentially planar rectangular panels attached to opposing valley and ridge cables.

One important concept behind the simple forms was the re-use of the fabric following the Expo.

Other projects included:

- Iranian Pavillion (2,500 sqm)

- Ferreo Pavillion (1,600 sqm)

- Institution Bologna Pavillion (4,500 sqm)

- Tent at the entrance (6,000 sqm)

For further details see HERE

- Spanish Pavilion at Dubai Expo 2020 (4726)

- Waitomo Glowworm Caves Visitor Centre

- Memorial Drive Tennis Centre Canopy (2021 DA)

- Chevron Renaissance

- Auckland Zoo Aviaries

- Inglis Selling Centre Fabric Roofs at Warwick Farm Racecourse (2018)

- The Cloud, Auckland

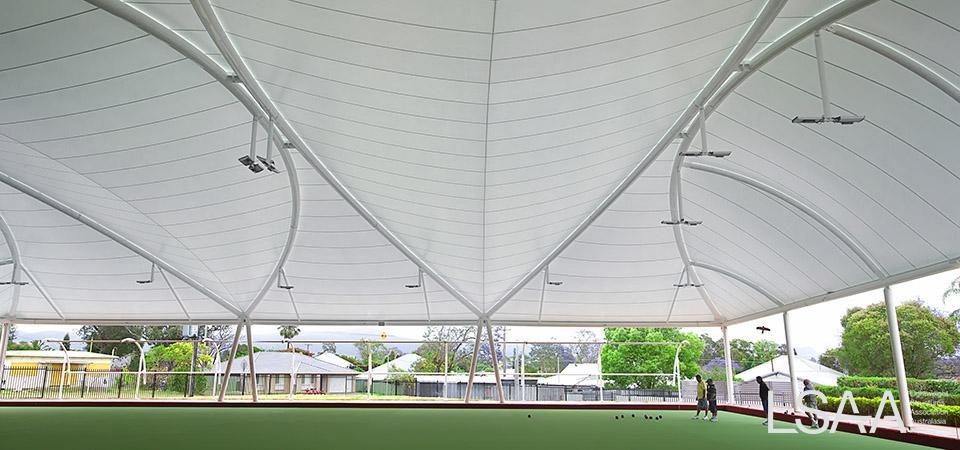

- Playford Bowls Club Triple Green Roof Cover Project (2018)

- The Glen Shopping Centre, Glen Waverley (Entry by Fabritecture)

- QUT Sports Field Car Park Project (2018)

- Sharjah Safari - Birds of Africa Aviary (DA 2022 Entry by Tensys)

- Macquarie University Campus Dining Room Project (2018)

- Souk Okaz Public Theatre

- Brisbane State Tennis Outdoor Show Courts

- The Farm - Anish Kapoor

- Marrara Tennis Centre Fabric Roof Project (2018)

- Pacific Fair Resort Roof

Page 2 of 4