This project was entered in the LSAA 2011 Design Awards (#7007)

PROJECT DESCRIPTION

This project was essentially a weather cover over a public space. During discussions with our sales team at the tendering stage it was clear that the project also had an element of environmental consideration. For this reason we developed a custom design that worked to these constraints.

The purpose according to builders was to create an inviting public recreation area. The architects specified a tensile membrane roof in order to cover the area while allowing natural light to enter the space.

APPLICATION OF PROJECT:

3 Pod like classrooms at Green School NZ

PROJECT DESCRIPTION:

To provide an outer skin from a material that can be recycled if/when replaced and also blends into environment. Wastage of non-recyclable materials to be kept to a minimum.

Also to provide the support frame to take the PVC membrane.

DESIGN / FABRICATION / INSTALLATION BRIEF

It was requested by the architect that we would supply a membrane solution for three-pod like classrooms for Green School New Zealand, to function as an aesthetic cladding and to create a ventilated thermal barrier to reduce a “heat soak effect” into the building. This was to complement the “green” label for the structure, reducing running costs and adding an organic look.

STRUCTURAL SYSTEMS

The overall complexity of the project was caused by the intriguing shape and challenging geometry, also the construction materials which were proposed.

The glulam timber beams implicated large tolerances on site, which required the steel components to be customized to match each of the three structures.

3d- digitizing of the design assisted by the construction of the tension-membranes. The high stretch of the fabric paired with the shape of the structures added the additional complexity of staged tensioning over multiple weeks.

MATERIALS

Mehler – Valmex Lodge de lux FR – 580gsm PVC

FABRICATION

The fabrication had complex geometry as the fabric had a high weft compensation which meant minimum tolerance to allow for the correct fit. The geometry for the fabric started with digital site measure using a Proliner first, followed by computer controlled cutting many checks and keder length dimensions to ensure accurate final panel size.

A similar process was used for the steel fabrication given the challenging geometry.

COLLABORATION, CONSTRUCTION AND MAINTENANCE

Being a bespoke membrane structure Cleland Construction Limited had to overcome the different approach from standard construction methodology and Fabric Structures & Cleland Construction work well to get the desired effect. This was mainly around a realization that fabrication off a 3D model was not going to create a successful outcome, therefore a proliner measure once the steel had been installed, then fabrication (with multiple QA check s) was agreed.

COSTS

Design – 12% Fabric – 6% Fabrication – 6% Steel – 50% Extrusion etc – 4% Installation – 22%

PROJECT CREDITS

Project Name Green School New Zealand

Location 406 Koru Road, Koru

City New Plymouth

Country New Zealand, 4374

Completion Date Oct-20

Category 2 Medium structures – 250m2 – 1000m2

Entrant Name Fabric Structures Limited

Address: 141 Dent Street,

Suburb: Central Business, Whangarei

Country: New Zealand, 0110

Telephone Land line: +64 9 4388343

Mobile: +64 275276452

Email Address:

Website address: www.fabricstructure.co.nz

Entrant Type / Role Designer / Fabricator / Installer

Project Client: Green School

Project Architect: Glen Brebner, Milca Severo, Boon

Structural Engineer: Fabspan/XiangDu

Specialist Consultant & Role: Kayne Jacobson, Project Manager

Building Contractor: Cleland Construction Limited

Fabricator(s): Fabric Structures Ltd – for membrane fabric

Others: Meco Engineering Co for Steel (under FSL contract)

APPLICATION OF PROJECT:

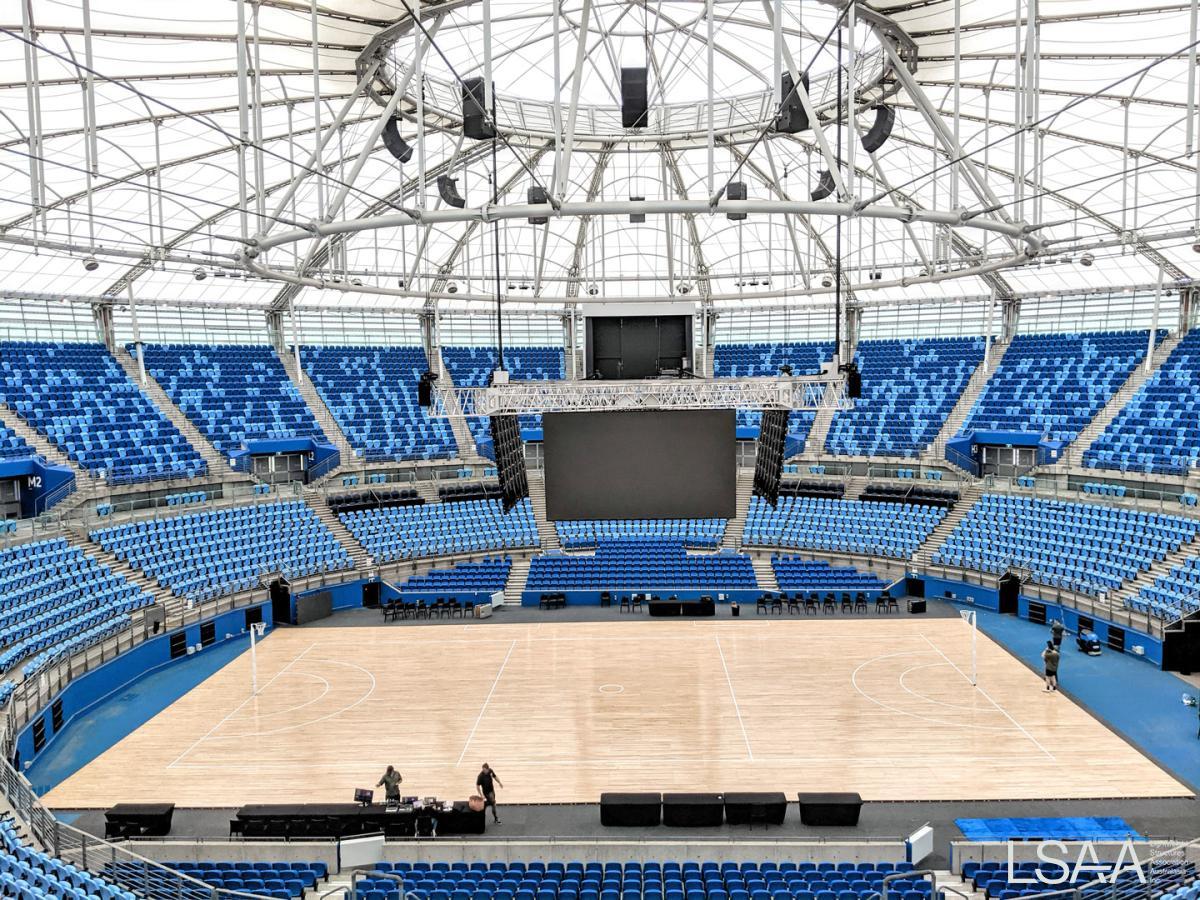

ETFE 600 sqm Skylight over an indoor swimming pool

PROJECT DESCRIPTION:

The Shore Physical Education Centre (SPEC) was built to deliver a suite of new flexible learning spaces including a multi-purpose sports complex and an indoor swimming pool. The 16 pillow, 3-layer ETFE skylights were a key part of the indoor swimming pool roof, designed to fill the indoor aquatic centre with natural lighting, while also providing a modern, highly aesthetic architectural feature to the roof.

DESIGN / FABRICATION / INSTALLATION BRIEF

The ETFE skylights located over the indoor swimming pool in the new Shore Physical Education Centre (SPEC) were required to interface with the surrounding Kingspan insulated roof system. We worked closely with the project Architect, Structural Engineer and Builder to develop design details that allowed the two elements to seamlessly connect.

Hiding of ductwork and the air supply plenum was important to the overall finish and as part of our value engineering approach to design, we proposed unique design touches, such as painting the air supply lines to match the internal fascia and keeping the ductwork hidden adjacent to structural elements in order to keep the premium-quality project finish required by the project brief.