The Link - Installation of the Membrane

APPLICATION OF PROJECT:

APPLICATION OF PROJECT:

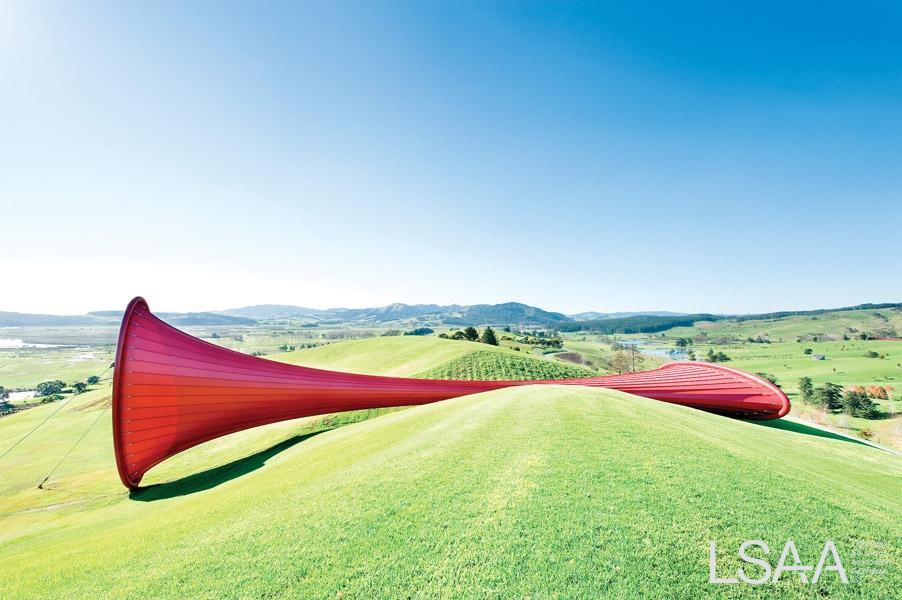

The Link Chadstone is a covered walkway between Chadstone shopping Centre and Hotel Chadstone Melbourne.

PROJECT DESCRIPTION:

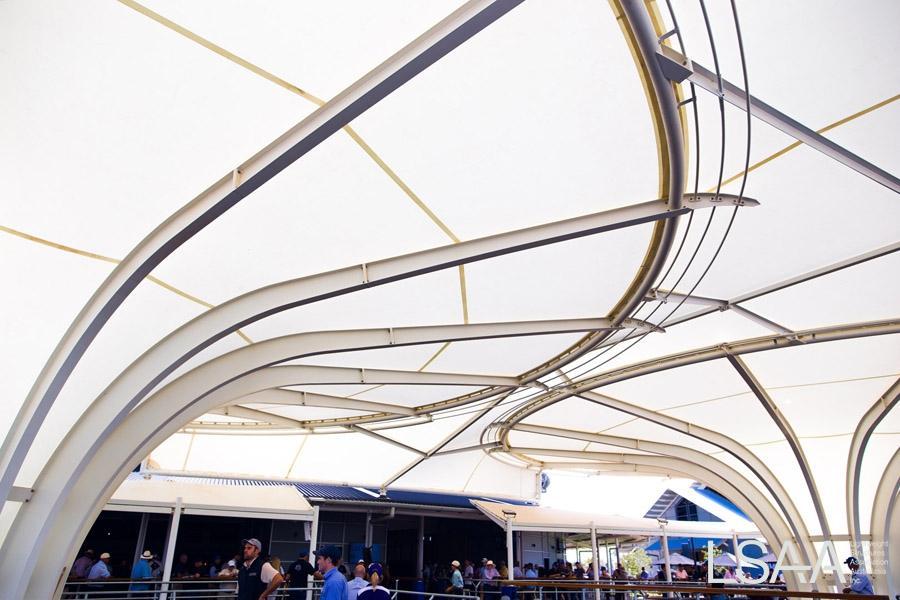

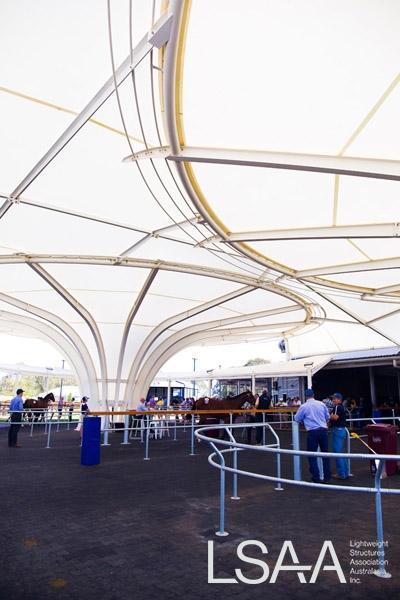

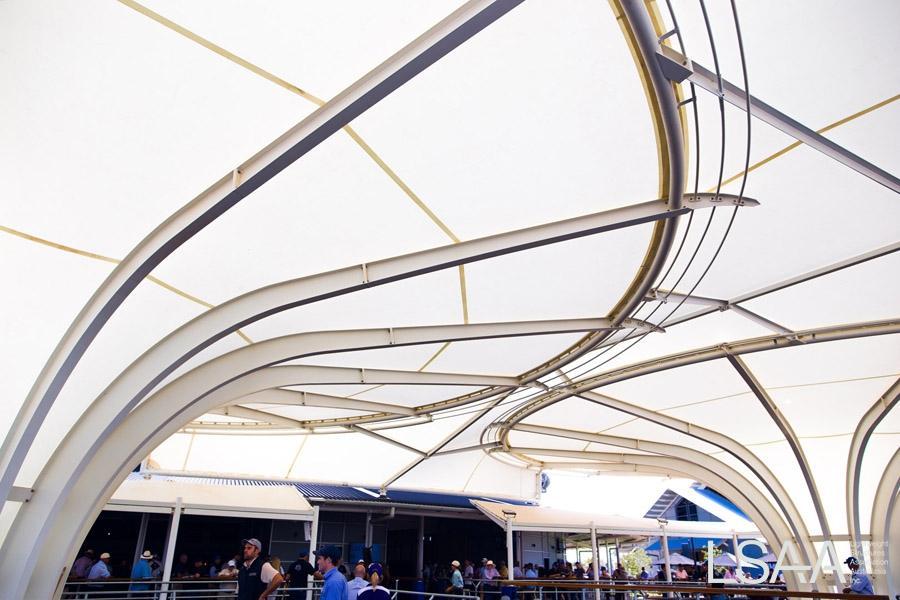

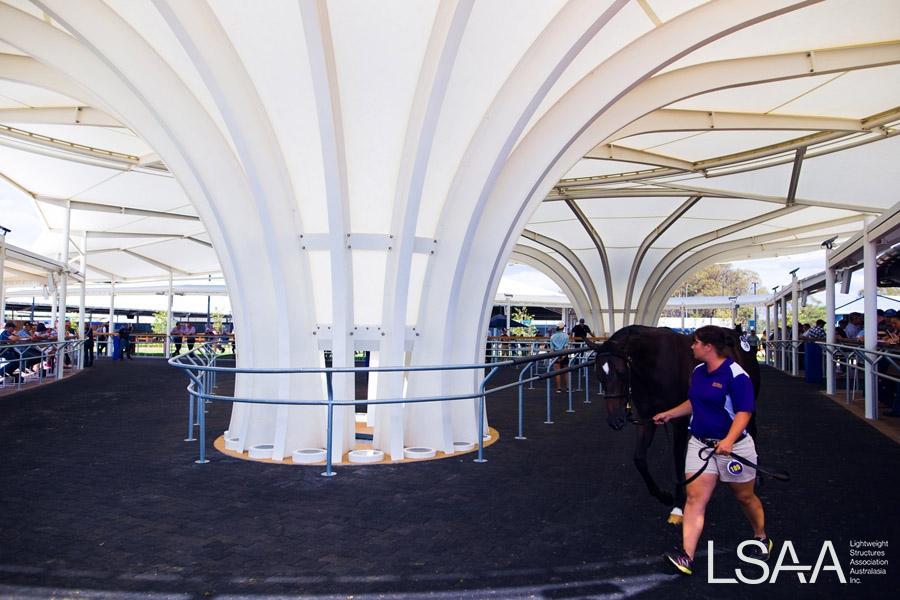

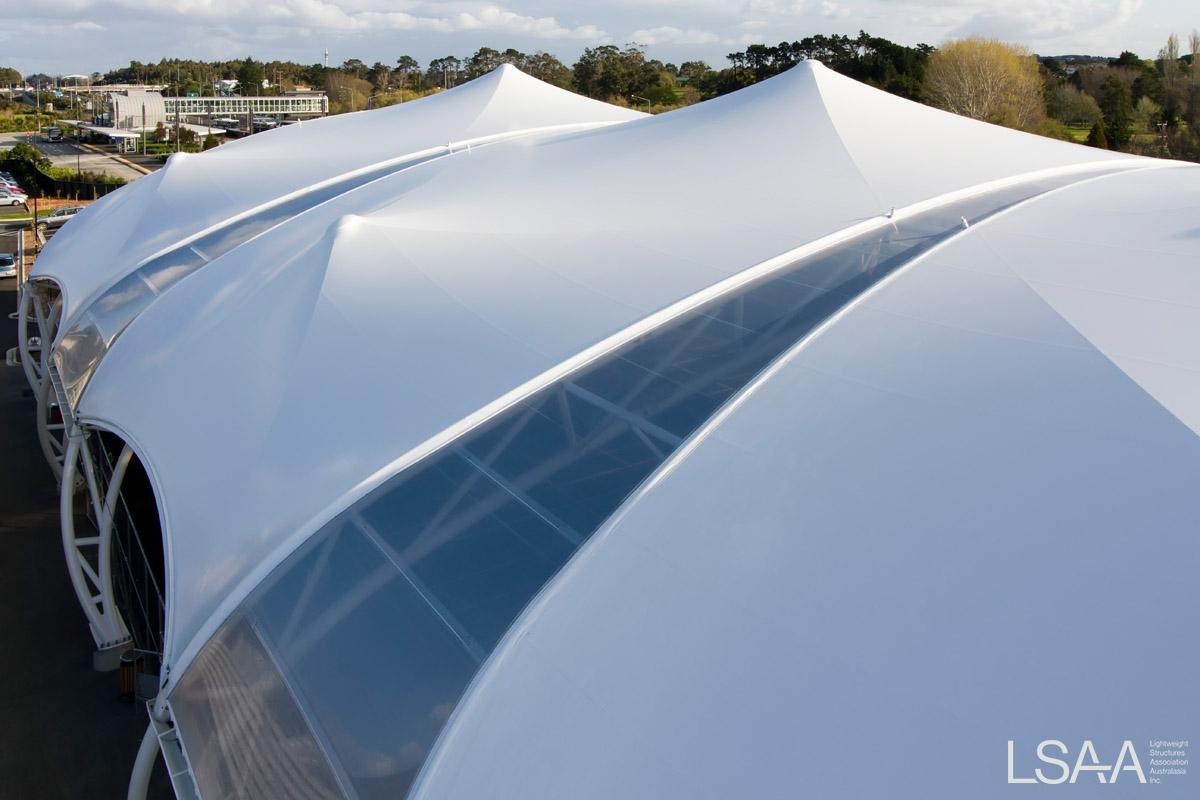

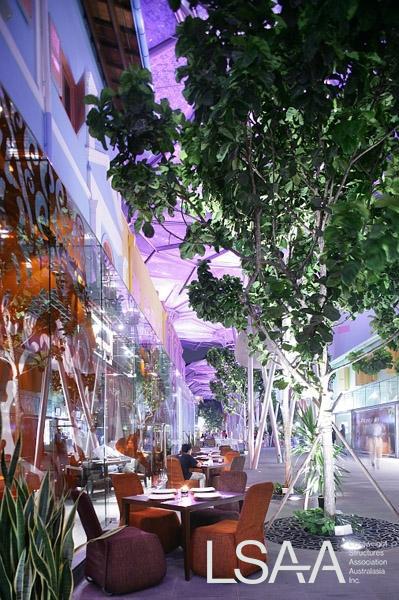

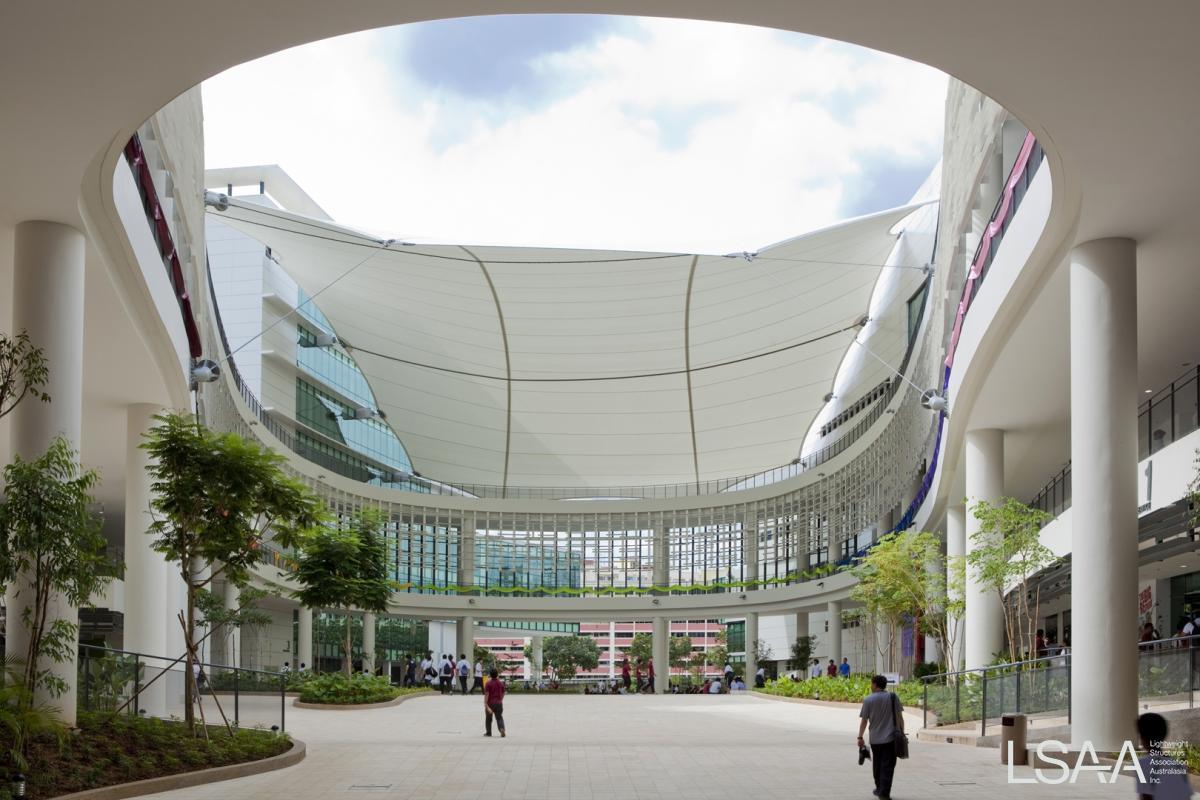

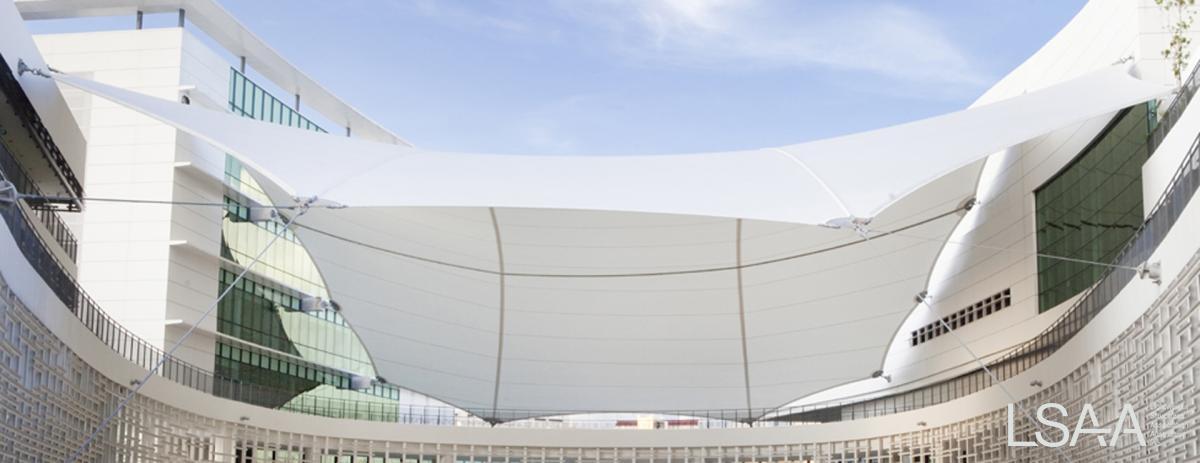

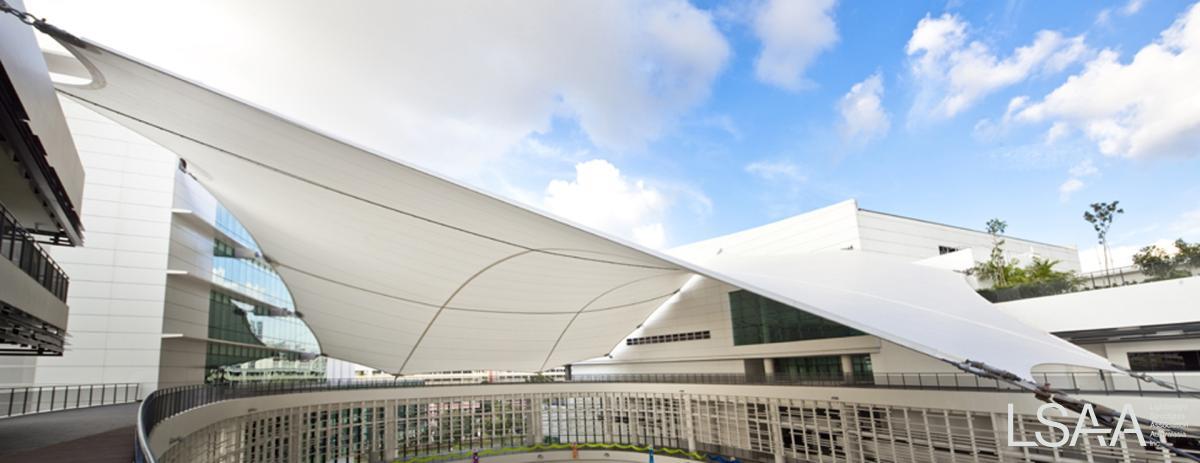

The Link walkway in Chadstone is a visually stunning fabric-over-glulam structure that provides easy covered access for patrons between the Chadstone Shopping Centre and Hotel Chadstone Melbourne.

Commissioned by leading Australian real estate investment trust Vicinity Centres, and completed in October 2019, The Link is a 100m arched walkway that soars up to 15m above the pedestrian zone and is covered with 1750m2 of high-translucency THV-coated PTFE fabric.

Designed to blur the lines between the retail, commercial and leisure zones of Chadstone’s high-end fashion shopping precinct with the newly opened Hotel Chadstone Melbourne, MGallery by Sofitel, The Link transforms part of a multi-level car park into a luxurious, cathedral-like promenade for shoppers and hotel guests.

DESIGN / FABRICATION / INSTALLATION BRIEF

The designing architect’s vision of The Link was to complement Chadstone Shopping Centre’s existing vaulted glass roof with an iconic light and airy structure created with glulam timber arches, covered with a semi-translucent tensile fabric membrane.

As the membrane contractors, the design and engineering challenge we faced on The Link was to deliver a premium tensile membrane finish to complement the projects’ luxury look and feel. With the aim to link the new 5-star Hotel Chadstone to the Chadstone Shopping Precinct – the membrane finish had to embrace the high-end, luxurious aesthetic of the project.

APPLICATION OF PROJECT:

APPLICATION OF PROJECT:

APPLICATION OF PROJECT:

APPLICATION OF PROJECT: